ASTM A106 grade b pipe suppliers, A106 Seamless Line Pipes Manufacturers, SA 106 Carbon Steel Pipe Suppliers, ASME SA106 Grade B Pipe, astm a106 grade b seamless pipe Manufacturers in India, astm A106 grade b welded pipe Manufacturers in India, astm a106 grade b seamless pipe Suppliers in India, astm a106 grade b welded pipe Suppliers in India

ASTM A106 grade b Seamless Tubes Manufacturers in India, ASTM A106 Pipe, ASME SA106 grade b, grade b seamless pipes Manufacturers in India, a106 grade b tubing, ASTM A106 Grade A, B Pipes, Tubes Manufacturers in India, ASTM A106 Grade B Erw Pipes Manufacturers in India, A106 Seamless Line Pipes Suppliers in India,

IBR Approved ASTM A106 Grade B Pipes, ASTM A106 Grade B Cold Drawn Seamless Pipes, A106 Grade B Seamless, A106 Grade B welded Tubes, Astm A106/asme Sa106 Grade B

ASTM A106 grade b Pipe Manufacturers In India

Galvanised Finish | Black Oil Paint | Heat Marked Pipes | Mill TC EN 10204 3.1 | Lab Test Reports | Ex-Stock

ASTM A106/ASME SA106 Grade B CS Seamless Pipes and Carbon Steel Welded Pipes Up To 36” Available for Immediate Supply

Buy High Quality ASTM A106 Grade B Seamless, Welded Pipes from Steel Pipes Online Industries – Call Us Now +919821125711, Mail Us sales@bhagwatisteelage.com

- What is ASTM A106 Pipe?

- EX stock of ISMT make Carbon Steel Pipe, ASTM A106 Grade B Pipe

- ASTM A106 Grade B Pipe Specifications

- ASTM A106 Grade B Pipe Grades & Stock

- ASTM A106 Grade B Pipe Latest Price

- ASTM A106 Grade B Pipe Grades

- ASTM A106 Grade B Pipe Stock Range

- Our Specialization in ASTM A106 Grade B Pipe

- Surplus stock of ASTM A106 Grade B Pipe

- ASTM A106 Grade B Pipe wall thickness

- ASTM A106 Grade B Pipe schedule chart

- ASTM A106 Grade B Pipe dimensions

- ASTM A106 Grade B Pipe chemical composition

- ASTM A106 Grade B Pipe Mechanical Properties

- ASTM A106 Grade B Pipe Packaging & Shipping

- ASTM A106 Grade B Pipe Pressure and Temperature Ratings

EX stock of ISMT make Carbon Steel Pipe, Carbon Steel Seamless Pipe, ASTM A106 Grade B Pipe

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ASTM A106 Grade b Pipe :

- ASTM A106 is Standard Specification for Seamless Carbon Steel Pipe for High-Temperature Service.

- A106 is a similar pipe in chemical composition but is intened for high temperature service (up to 750 Degs F). It is a seamless pipe.

At least in the US, there is usually A53 for welded pipe while A106 is seamless. If you ask for A53 in the US they will quote A106 as an alternate. - This specification covers seamless carbon steel pipe for high-temperature service (Note 1) in NPS 1/8 to NPS 48 [DN 6 to DN 1200] (Note 2) inclusive, with nominal (average) wall thickness as given in ASME B36.10. It shall be permissible to furnish pipe having other dimensions provided such pipe complies with all other requirements of this specification. Pipe ordered under this specification shall be suitable for bending, flanging, and similar forming operations, and for welding. When the steel is to be welded, it is presupposed that a welding procedure suitable to the grade of steel and intended use or service will be utilized.

ASTM A106 Grade A, B, C Carbon Steel Seamless Pipes, Carbon Steel Seamless Tubes, ASTM A106 Grade B Line Pipes Exporter, Suppliers. We are the Approved Suppliers and wanders’ of HPCL , IFFCO, NRL Limited , Torrent Power since one Decade.

10,000 sqft, Navi Mumbai, Kalamboli

| Ready Stock Available | |

|---|---|

| ASTM A106 grade A Pipes , Tubes | 100 ton |

| ASTM A106 grade B Pipes , Tubes | 500 ton |

Buy High Quality ASTM A106 Grade B, With Mill Certification – CALL US NOW ! Exports Is Our Specialty

ASTM A106 Grade B Seamless Pipes Exporter, Supplier and Worldwide Supplier

ASTM A106 Grade B carbon steel pipes are widely available and relatively affordable, making it a popular choice for very large projects such as pipelines. Steel Pipes Online stocks and supplies full range of ASTM A106 Grade B pipes and tubes. ASTM/ASME A-106/SA-106 grade seamless pipes is one of our most widely used grade of carbon steel and is readily available ex-stock for all standard thicknesses up to SCH160. Steel Pipes Online is a reputed distributor of ASTM A106 Grade B pipes by Supply in India such as MSL, ISMT and JINDAL SAW.

ASTM/ASME A106/SA106 carbon steel seamless pipes are used in industrial applications involving high heat, including process piping, boiling plants, compression stations and refineries.

ASTM A106 Grade B Steel Pipes, ASTM A106 Grade B Steel Tubes Specifications, Stock And Supply Range

ASTM A106 Grade B Carbon Steel Pipes

- Size Range: 1/2” NB to 36” NB

- Thickness: SCH 40, SCH 80, SCH 160, SCH XS, SCH XXS, All Schedules

- Applications: Oil Refineries, Petrochemicals, Power Generation (Nuclear/Thermal), Steel, Sugar, Boiler Equipments, Pressure Vessels and General Engineering Purposes

End Connections for Line Pipes: Plain, Bevel, Screwed, Threaded

Type: Seamless / ERW / Welded / Fabricated / CDW

Form: Round Pipes/Tubes, Square Pipes/Tubes, Rectangular Pipe/Tubes, Coiled Tubes, “U” Shape, Pan Cake Coils, Hydraulic Tubes

Length: Single Random, Double Random & Required Length, Custom Size – 12 Meter lengths

End: Plain End, Beveled End, Treaded

End Protection: Plastic Caps

Outside Coating: Black Painting, Anti-Corrosion Oil, Galvanised Finish, Finish as per customer Requirements

Inspection, Test Reports: Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports, India Boiler Regulations (IBR) Test Certificate

Packing: Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests

Specials: Sizes and Specifications other than above can be Supplier on request

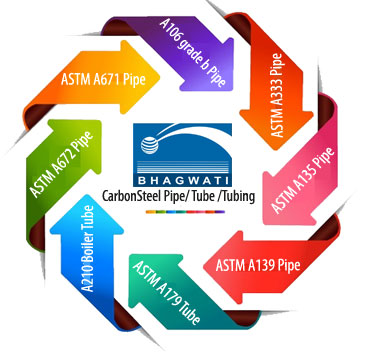

| High Temperature Seamless Pipe | ASTM A106 Gr. B/C, API 5L Gr. B, ASTM A53 Gr. B |

|---|---|

| Heat Exchanger Seamless Tube | ASTM A179 |

| Low Temperature Seamless Pipe | ASTM A333 Gr. 3/6 |

| Low Temperature Seamless Tube | ASTM A334 Gr. 6 |

| High Yield Seamless Pipe | API 5L Gr. X42/X46/X52/X56/X60/X65/X70/X80 PSL-1/PSL-2 |

| High Yield Seamless Pipe | ISO 3183 Gr.L245, L290, L320, L360, L390, L415, L450, L485 |

| Atmospheric & Low Temp EFW Pipes | ASTM A671 Gr. CC60/CC65/CC70 |

| High Pressure & Moderate Temp EFW Pipes | ASTM A672 Gr. B60/B65/B70/C55/C60/C65/C70 |

| High Yield ERW/SAW Pipe | API 5L Gr. X42/X46/X52/X56/X60/X65/X70/X80 PSL-1/PSL-2 |

| High Yield ERW/SAW Pipe | ISO 3183 Gr.L245, L290, L320, L360, L390, L415, L450, L485 |

astm a106 grade b pipe price, astm a106 grade b price, a106 gr b pipe cost, a106 grade b tubing price

- astm a106 gr.b seamless steel pipe

US $600-860 / Ton (FOB Price) - a106 gr.b seamless pipe

US $500-1000 / Metric Ton (FOB Price) - ASTM A106 seamless steel pipe

US $800-900 / Metric Ton (FOB Price) - Steel Piping,Steel Tube,Carbon Steel Pipe

US $470.0 / Ton (FOB Price) - ASTM A106 GR.B Seamless Carbon steel pipe/tube

US $600-1500 / Ton (FOB Price) - black steel seamless pipes sch40 astm a106

US $300-600 / Ton (FOB Price) - ASTM A106 grade Hot rolled seamless steel pipe

US $450.0-460.0 / Tons (FOB Price) - ASTM A106 schedule 40 seamless carbon steel pipe

US $500-800 / Ton (FOB Price) - astm a106 erw carbon steel line pipe

US $600-800 / Ton (FOB Price) - seamless pipes sch40 astm a106

US $500-1500 / Metric Ton (FOB Price) - ASTM A106 Grade B Seamless Steel Pipe

US $1-700 / Ton (FOB Price) - ASTM A106 Grade B

US $530-750 / Ton (FOB Price) - astm a106 grade b sch40 seamless steel pipe

US $580-650 / Metric Ton (FOB Price) - ASTM A106 Grade B Carbon Steel Pipe

US $650-920 / Ton (FOB Price) - astm a106 a53 seamless carbon steel pipe

US $500-1000 / Ton (FOB Price) - ASTM A106 Grade B seamless carbon steel pipe

US $430-650 / Ton (FOB Price) - asme sa106 grade b astm a106 grade b seamless pipe

US $500-600 / Ton (FOB Price) - ASTM A 106GRB carbon seamless steel pipes

US $600-1219 / Ton (FOB Price)

ASTM A106 Grade B Pipe Stock

dimensions of ASTM A333 Seamless Steel Pipes, ASTM A333 Low Temperature Seamless Steel Tubing

| Carbon Steel Welded and seamless pipe

1/2 to 6 NPS |

Dimensions and weights section modulus and gallons capacity per linear foot |

| Size NPS | Pipe O.D. | Wall Thickness | Pipe I.D. | Weight per Foot | Standard to XXHY | Schedule Pipe # |

Section Modulus | Gallon Capacity Per Linear Foot |

|---|---|---|---|---|---|---|---|---|

| 1/2 | 0.84 | 0.109 | 0.622 | 0.85 | STD | 40 | .0407 | .0158 |

| 0.147 | 0.546 | 1.09 | XHY | 80 | .0478 | .0122 | ||

| 0.188 | 0.464 | 1.31 | 160 | .0528 | .0088 | |||

| 0.294 | 0.252 | 1.72 | XXHY | .0577 | .0026 | |||

| 3/4 | 1.05 | 0.113 | 0.824 | 1.13 | STD | 40 | .0705 | .0277 |

| 0.154 | 0.742 | 1.48 | XHY | 80 | .0853 | .0225 | ||

| 0.219 | 0.612 | 1.95 | 160 | .1006 | .0153 | |||

| 0.308 | 0.434 | 2.44 | XXHY | .1103 | .0077 | |||

| 1 | 1.315 | 0.133 | 1.049 | 1.68 | STD | 40 | .1328 | .0449 |

| 0.179 | 0.957 | 2.17 | XHY | 80 | .1606 | .0374 | ||

| 0.250 | 0.815 | 2.85 | 160 | .1904 | .0271 | |||

| 0.358 | 0.599 | 3.66 | XXHY | .2136 | .0146 | |||

| 1 1/4 | 1.66 | 0.140 | 1.380 | 2.27 | STD | 40 | .2346 | .0777 |

| 0.191 | 1.278 | 3.00 | XHY | 80 | .2913 | .0666 | ||

| 0.250 | 1.160 | 3.77 | 160 | .3421 | .0549 | |||

| 0.382 | 0.896 | 5.22 | .4110 | .0328 | ||||

| 1 1/2 | 1.90 | 0.145 | 1.610 | 2.72 | STD | 40 | .3262 | .1058 |

| 0.200 | 1.500 | 3.63 | XHY | 80 | .4118 | .0918 | ||

| 0.281 | 1.338 | 4.86 | 160 | .5079 | .0730 | |||

| 0.400 | 1.100 | 6.41 | .5977 | .0494 | ||||

| 2 | 2.375 | 0.109 | 2.157 | 2.64 | 10 | .4205 | .1898 | |

| 0.154 | 2.067 | 3.66 | STD | 40 | .5606 | .1743 | ||

| 0.218 | 1.939 | 5.03 | XHY | 80 | .7309 | .1534 | ||

| 0.250 | 1.875 | 5.68 | .8045 | .1434 | ||||

| 0.281 | 1.813 | 6.29 | .8666 | .1344 | ||||

| 0.344 | 1.687 | 7.47 | 160 | .9806 | .1161 | |||

| 0.436 | 1.503 | 9.04 | XXHY | 1.1043 | .0922 | |||

| 2 1/2 | 2.875 | 0.120 | 2.635 | 3.53 | 10 | .6870 | .2833 | |

| 0.203 | 2.469 | 5.80 | STD. | 40 | 1.0640 | .2487 | ||

| 0.216 | 2.443 | 6.14 | 1.1169 | .2435 | ||||

| 0.250 | 2.375 | 7.02 | 1.2468 | .2301 | ||||

| 0.276 | 2.323 | 7.67 | XHY | 80 | 1.3386 | .2202 | ||

| 0.375 | 2.125 | 10.02 | 160 | 1.6371 | .1842 | |||

| 0.552 | 1.771 | 13.71 | XXXHY | 1.9971 | .1280 | |||

| 3 | 3.50 | 0.120 | 3.260 | 4.34 | 1.0411 | .4336 | ||

| 0.156 | 3.188 | 5.58 | 1.3122 | .4147 | ||||

| 0.172 | 3.156 | 6.12 | 1.4265 | .4064 | ||||

| 0.188 | 3.124 | 6.66 | 1.5342 | .3984 | ||||

| 0.216 | 3.068 | 7.58 | STD. | 40 | 1.7241 | .3840 | ||

| 0.250 | 3.000 | 8.69 | 1.9372 | .3672 | ||||

| 0.281 | 2.938 | 9.67 | 2.1207 | .3521 | ||||

| 0.300 | 2.900 | 10.26 | XHY | 80 | 2.2253 | .3431 | ||

| 0.438 | 2.624 | 14.34 | 160 | 2.8774 | .2811 | |||

| 0.600 | 2.300 | 18.6 | XXHY | 3.4243 | .2158 | |||

| 3 1/2 | 4.0 | 0.120 | 3.760 | 4.98 | 10 | 1.3776 | .5768 | |

| 0.226 | 3.548 | 9.12 | STD. | 140 | 2.3939 | .5136 | ||

| 0.250 | 3.500 | 10.02 | 2.6001 | .4998 | ||||

| 0.281 | 3.438 | 11.17 | 2.8562 | .4821 | ||||

| 0.318 | 3.364 | 12.52 | XHY | 80 | 3.1400 | .4617 | ||

| 0.636 | 2..728 | 22.87 | XXHY | 4.8795 | .3085 | |||

| 4 | 4.5 | 0.120 | 4.260 | 5.62 | 10 | 1.7612 | .7404 | |

| 0.156 | 4.188 | 7.24 | 2.2354 | .7156 | ||||

| 0.188 | 4.124 | 8.67 | 2.6296 | .6942 | ||||

| 0.203 | 4.094 | 9.32 | 2.8173 | .6838 | ||||

| 0.219 | 4.062 | 10.02 | 3.0184 | .6725 | ||||

| 0.237 | 4.026 | 10.80 | STD. | 40 | 3.2145 | .6613 | ||

| 0.250 | 4.000 | 11.36 | 3.3611 | .6528 | ||||

| 0.281 | 3.938 | 12.67 | 60 | 3.7021 | .6326 | |||

| 0.312 | 3.876 | 13.97 | 4.0273 | .6126 | ||||

| 0.337 | 3.826 | 15.00 | XHY | 80 | 4.2713 | .5972 | ||

| 0.438 | 3.624 | 19.02 | 120 | 5.1790 | .5361 | |||

| 0.531 | 3.438 | 22.53 | 160 | 5.8997 | .4822 | |||

| 0.674 | 3.152 | 27.57 | XXHY | 6.7927 | .4054 | |||

| 5 | 5.563 | 0.188 | 5.187 | 10.80 | 4.1161 | 1.0979 | ||

| 0.219 | 5.125 | 12.51 | 4.7279 | 1.0716 | ||||

| 0.258 | 5.047 | 14.63 | STD. | 40 | 5.4500 | 1.0391 | ||

| 0.281 | 5.001 | 15.87 | 5.8644 | 1.0204 | ||||

| 0.312 | 4.939 | 17.51 | 6.4074 | .99647 | ||||

| 0.344 | 4.875 | 19.19 | 6.9358 | .9696 | ||||

| 0.375 | 4.813 | 20.80 | XHY | 80 | 7.4300 | .9449 | ||

| 0.500 | 4.563 | 27.06 | 120 | 9.2534 | .8495 | |||

| 0.625 | 4.313 | 32.99 | 160 | 10.7976 | .7590 | |||

| 0.750 | 4.063 | 38.59 | XXHY | 12.0954 | .6734 | |||

| 6 | 6.625 | 0.109 | 6.407 | 7.59 | 5 | 3.5769 | 1.6748 | |

| 0.134 | 6.357 | 9.30 | 10 | 4.3475 | 1.6488 | |||

| 0.156 | 6.313 | 10.79 | 5.0107 | 1.6260 | ||||

| 0.188 | 6.249 | 12.94 | 5.9351 | 1.5937 | ||||

| 0.203 | 6.219 | 13.94 | 6.3804 | 1.5780 | ||||

| 0.219 | 6.187 | 15.00 | 6.8261 | 1.5620 | ||||

| 0.250 | 6.125 | 17.04 | 7.6905 | 1.5306 | ||||

| 0.280 | 6.065 | 18.99 | STD. | 40 | 8.4958 | 1.5008 | ||

| 0.312 | 6.001 | 21.06 | 9.3416 | 1.4688 | ||||

| 0.344 | 5.937 | 23.10 | 10.111 | 1.4391 | ||||

| 0.375 | 5.875 | 25.05 | 10.893 | 1.4082 | ||||

| 0.432 | 5.761 | 28.60 | XHY | 80 | 12.224 | 1.3541 | ||

| 0.500 | 5.625 | 32.74 | 13.711 | 1.2909 | ||||

| 0.562 | 5.501 | 36.43 | 120 | 14.9806 | 1.2346 | |||

| 0.625 | 5.375 | 40.09 | 16.1821 | 1.1787 | ||||

| 0.719 | 5.187 | 45.39 | 160 | 17.8243 | 1.0977 | |||

| 0.864 | 4.897 | 53.21 | XXHY | 20.025 | .9784 | |||

| 1.000 | 4.625 | 60.13 | 21.7719 | .8727 | ||||

| 1.125 | 4.375 | 66.14 | 23.1237 | .7809 |

are you looking for jsl make ASTM A106 Grade B Pipe, carbon steel pipe, carbon steel Tube Buy directly from dealer of jindal limited

|

|

ASTM A106 Seamless Steel Pipes, ASTM A106 Seamless Steel Tubes Chemical Composition

Chemical Composition (%) |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Grade |

C(Max) |

Mn |

Si(Min) |

Cu(Max) |

Ni(Max) |

Cr(Max) |

Mo(Max) |

V(Max) |

P(Max) |

S(Max) |

A |

0.25 |

0.27~0.93 |

0.1 |

0.4 |

0.4 |

0.4 |

0.15 |

0.08 |

0.035 |

0.035 |

B |

0.3 |

0.29~1.06 |

0.1 |

0.4 |

0.4 |

0.4 |

0.15 |

0.08 |

0.035 |

0.035 |

C |

0.35 |

0.29~1.06 |

0.1 |

0.4 |

0.4 |

0.4 |

0.15 |

0.08 |

0.035 |

0.035 |

ASTM A106 Seamless Steel Pipes, ASTM A106 Seamless Steel Tubes Mechanical Properties

Mechanical Properties: |

||

|---|---|---|

Grade |

Tensile Strength (Mpa), Min. |

Yield Strength (Mpa), Min. |

A |

330 |

205 |

B |

415 |

240 |

C |

485 |

275 |

ASTM A106 Seamless Steel Pipes, ASTM A106 Seamless Steel Tubes Tolerance Specifications

NPS |

1/8″ to 1 1/2″ |

Over 1 1/2″ to 4″ |

Over 4″ to 8″ |

Over 8″ to 18″ |

Over 18″ to 26″ |

Over 26″ to 34″ |

Over 34″ to 48″ |

|---|---|---|---|---|---|---|---|

OD Tolerance |

+/- 0.4 |

+/- 0.8 |

+1.6, -0.8 |

+2.4, -0.8 |

+3.2, -0.8 |

+4.0, -0.8 |

+4.8, -0.8 |

WT Tolerance |

+/- 12.5% |

||||||

Weight Tolerance |

+10%, -3.5% |

||||||

ASTM A106 grade b Pipe equivalent

| Former | New | |||

|---|---|---|---|---|

| Execution | Standard | Material | Standard | Material |

Seamless |

ASTM A106 |

GRADE B |

EN 10216-2 |

P265GH |

Seamless |

ASTM A333 |

GRADE 6 |

EN 10216-4 |

P265NL |

Welded |

API 5L |

Grade B |

EN 10208-2 |

L245NB |

Welded |

API 5L |

Grade X52 |

EN 10208-2 |

L360NB |

Seamless |

API 5L |

Grade B |

EN 10208-2 |

L245NB |

Seamless |

API 5L |

Grade X52 |

EN 10208-2 |

L360NB |

ASTM A106 Gr. B Pipe Mechanical Properties – Tensile Requirements

ASTM A106 Grade B |

|

|---|---|

| Tensile Strength, min, psi | 60,000 |

| astm a106 grade b yield strength , min, psi | 35,000 |

ASTM A106 Grade B Carbon Steel Pipes Size & Stock Range

| Pipe/ Tube Type | NB Sizes | Sch 5 | Sch 10 | Sch 40 | Sch 80 | Sch 160 |

|---|---|---|---|---|---|---|

| ASTM A106 Grade B Pipe | 1/2 | |||||

| ASTM A106 Grade B Pipe | 3/4 | |||||

| ASTM A106 Grade B Pipe | 1 | |||||

| ASTM A106 Grade B Pipe | 1.25 | |||||

| ASTM A106 Grade B Pipe | 1.5 | |||||

| ASTM A106 Grade B Pipe | 2 | |||||

| ASTM A106 Grade B Pipe | 2.5 | |||||

| ASTM A106 Grade B Pipe | 3 | |||||

| ASTM A106 Grade B Pipe | 3.5 | |||||

| ASTM A106 Grade B Pipe | 4 | |||||

| ASTM A106 Grade B Pipe | 5 | |||||

| ASTM A106 Grade B Pipe | 6 | |||||

| ASTM A106 Grade B Pipe | 8 | |||||

| ASTM A106 Grade B Pipe | 10 | |||||

| ASTM A106 Grade B Pipe | 12 | |||||

| ASTM A106 Grade B Pipe | 14 | |||||

| ASTM A106 Grade B Pipe | 16 | |||||

| ASTM A106 Grade B Pipe | 18 | |||||

| ASTM A106 Grade B Pipe | 20 | |||||

| ASTM A106 Grade B Pipe | 22 | |||||

| ASTM A106 Grade B Pipe | 24 |

ASTM A106 Grade B Pipe Ready Stock Available for Oil & Gas Industry

ASTM A106 Grade B Pipe Ready Stock Available with supplementary tests/ HIC Test

|

|

|

ASTM A106 Grade B Pipe Yield and Tensile Strength

| Seamless | Grade A | Grade B | Grade C |

|---|---|---|---|

| Tensile Strength, min., psi | 48,000 | 60,000 | 70,000 |

| Yield Strength, min., psi | 30,000 | 35,000 | 40,000 |

Pressure Temperature Rating of ASTM A106 Grade B Pipes

ASTM A106/ ASME SA 106 gr b allowable stress

Maximum Allowable Pressure (psig) |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| A106 Pipe Size (inches) |

Pipe Schedule | Temperature (oF) | ||||||||

| 100 | 200 | 300 | 400 | 500 | 600 | 650 | 700 | 750 | ||

| 1" | 401) | 2857 | 2857 | 2857 | 2857 | 2857 | 2857 | 2857 | 2743 | 2476 |

| 802) | 3950 | 3950 | 3950 | 3950 | 3950 | 3950 | 3950 | 3792 | 3423 | |

| 160 | 5757 | 5757 | 5757 | 5757 | 5757 | 5757 | 5757 | 5526 | 4989 | |

| 1 1/2" | 40 | 2116 | 2116 | 2116 | 2116 | 2116 | 2116 | 2116 | 2032 | 1834 |

| 80 | 2983 | 2983 | 2983 | 2983 | 2983 | 2983 | 2983 | 2864 | 2585 | |

| 160 | 4331 | 4331 | 4331 | 4331 | 4331 | 4331 | 4331 | 4157 | 3753 | |

| 2" | 40 | 1783 | 1783 | 1783 | 1783 | 1783 | 1783 | 1783 | 1712 | 1545 |

| 80 | 2575 | 2575 | 2575 | 2575 | 2575 | 2575 | 2575 | 2472 | 2232 | |

| 160 | 4217 | 4217 | 4217 | 4217 | 4217 | 4217 | 4217 | 4049 | 3655 | |

| 3" | 40 | 1693 | 1693 | 1693 | 1693 | 1693 | 1693 | 1693 | 1625 | 1467 |

| 80 | 2394 | 2394 | 2394 | 2394 | 2394 | 2394 | 2394 | 2298 | 2074 | |

| 160 | 3600 | 3600 | 3600 | 3600 | 3600 | 3600 | 3600 | 3456 | 3120 | |

| 4" | 40 | 1435 | 1435 | 1435 | 1435 | 1435 | 1435 | 1435 | 1378 | 1244 |

| 80 | 2075 | 2075 | 2075 | 2075 | 2075 | 2075 | 2075 | 1992 | 1798 | |

| 160 | 3376 | 3376 | 3376 | 3376 | 3376 | 3376 | 3376 | 3241 | 2926 | |

| 5" | 40 | 1258 | 1258 | 1258 | 1258 | 1258 | 1258 | 1258 | 1208 | 1090 |

| 80 | 1857 | 1857 | 1857 | 1857 | 1857 | 1857 | 1857 | 1783 | 1610 | |

| 160 | 3201 | 3201 | 3201 | 3201 | 3201 | 3201 | 3201 | 3073 | 2774 | |

| 6" | 40 | 1143 | 1143 | 1143 | 1143 | 1143 | 1143 | 1143 | 1098 | 991 |

| 80 | 1794 | 1794 | 1794 | 1794 | 1794 | 1794 | 1794 | 1722 | 1554 | |

| 160 | 3083 | 3083 | 3083 | 3083 | 3083 | 3083 | 3083 | 2960 | 2672 | |

| 8" | 40 | 1006 | 1006 | 1006 | 1006 | 1006 | 1006 | 1006 | 966 | 872 |

| 80 | 1586 | 1586 | 1586 | 1586 | 1586 | 1586 | 1586 | 1523 | 1375 | |

| 160 | 2976 | 2976 | 2976 | 2976 | 2976 | 2976 | 2976 | 2857 | 2579 | |

| 10" | 40 | 913 | 913 | 913 | 913 | 913 | 913 | 913 | 876 | 791 |

| 80 | 1509 | 1509 | 1509 | 1509 | 1509 | 1509 | 1509 | 1448 | 1308 | |

| 160 | 2950 | 2950 | 2950 | 2950 | 2950 | 2950 | 2950 | 2832 | 2557 | |

ASTM A106 Grade B Pipe Schedule Chart & Wall Thickness

Nominal wall thickness for ASTM A106 Grade B Pipe/ ASTM A106 seamless and welded steel pipes according ANSI B36.10:

Marking Requirements

Marking Requirements