ASTM A333 Grade 6 Carbon Steels Material, ASTM SA 333 Low Temperature Pipe, ASTM A333 (Asme S/a-333) Pipe, A333 Pipe Grades 1, 3, 4, 6, 7, 8, 9, 10, 11 Manufacturers in India, ASTM A333 GR. 3 Carbon Steel Seamless Pipe suppliers, Astm A333 Grade 3 Pipe Manufacturers in India, Astm A333 Grade 1 Pipe Manufacturers in India, Astm A333 Grade 3 Erw Pipes, ASTM A333 grade 8 Manufacturers in India, ASTM A333 Pipe Manufacturers in India, ASTM A333 Pipe Suppliers in India

ASTM A333 Grade 6 Seamless Pipe, ASTM A333 Grade 6 Low Temperature Carbon Steel Pipes, ASTM A333 Grade 6 Pipes, ASTM A333 Grade 6 Tubes, ASTM A333 Grade 6 ERW Pipes, ASTM A333 Seamless Line Pipes at most attractive price offer, ASTM A333 GR. 3 Carbon Steel Seamless Pipe, ASTM A333 GR. 6 Carbon Steel Seamless Pipe, ASTM A333 GR. 6 Carbon Steel Welded Pipe, ASTM A333 GR. 6 Carbon Steel ERW Pipe

Ibr Approved Astm A333 Gr. 6 Seamless Tubes, Grade 6 Low Temperature Tubes, A333 Cold Drawn Seamless Pipes Suppliers in India, Astm A333 Grade 3 Seamless Pipe, ASTM A333 Grade 6 Carbon Steel Welded Pipe suppliers, ASTM A333 GRADE 3 ERW PIPES, ASTM A333 GR. 3 Carbon Steel Seamless Pipe manufacturers in India, A333 Grade Pipe, A333 Grade 1 Pipe, A333 Grade 6 Pipe, A333 Grade 3 Pipe, astm a333 grade 3 low temperature tubing, astm a333 grade 1 low temperature tubing

ASTM A333 Pipe Manufacturers in India, ASTM A333 Pipe Suppliers

- EX stock of ISMT make ASME SA333 Pipe, Carbon Steel Pipe, Carbon Steel Tube

- ASTM A333 Pipe/ASME SA333 Pipe Specifications

- ASTM A333 Pipe/ASME SA333 Pipe Grades & Stock

- ASTM A333 Pipe/ASME SA333 Pipe Latest Price

- ASTM A333 Pipe/ASME SA333 Pipe Grades

- ASTM A333 Pipe/ASME SA333 Pipe Stock Range

- Our Specialization in ASTM A333 Pipe/ASME SA333 Pipe

- Surplus stock of ASTM A333 Pipe/ASME SA333 Pipe

- ASTM A333 Pipe/ASME SA333 Pipe wall thickness

- ASTM A333 Pipe/ASME SA333 Pipe schedule chart

- ASTM A333 Pipe/ASME SA333 Pipe dimensions

- ASTM A333 Pipe/ASME SA333 Pipe chemical composition

- ASTM A333 Pipe/ASME SA333 Pipe Mechanical Properties

- ASTM A333 Pipe/ASME SA333 Pipe Packaging & Shipping

- ASTM A333 Pipe/ASME SA333 Pipe Pressure and Temperature Ratings

EX stock of ISMT make ASTM A333 Pipe/ASME SA333 Pipe, Carbon Steel Pipe, Carbon Steel Seamless Pipe, Carbon Steel ERW Pipe

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

What Is Astm A333 Seamless Pipes?

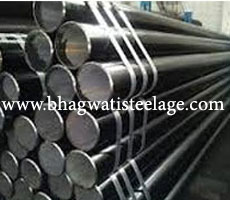

ASTM A333/ASME SA333 Grade 6 Carbon Steel Seamless Pipes, Carbon Steel Seamless Tubes, ASTM A333/ASME SA333 Grade 6 Line Pipes supplied to Oil & Gas Industry. ASTM A333 (ASME S/A-333) Pipes grades permit low temperature service. This specification covers nominal (average) walled pipe almost exclusively in seamless. Several grades of ferritic steel are included. Some product sizes may not be available under this specification because heavier wall thicknesses have an adverse effect on low-temperature impact properties. A333 pipe is furnished to nine different grades designated by numbers 1, 3, 4, 6, 7, 8, 9, 10, & 11.

ASTM A333 GRADE 1, 3, 4, 6, 7, 8, 9, 10 & 11. Low Temperature Carbon Steel Seamless Pipe

ASTM A333 is the Standard Specification for Seamless and Welded Steel Pipe for Low-Temperature Service. ASTM A333 standard covers wall seamless and welded carbon and alloy steel pipe intended for use at low temperatures. Tensile tests, impact tests, hydrostatic tests, and nondestructive electric tests shall be made in accordance to specified requirements. ASTM A333/ASME SA333 Grade 6 CS Seamless Pipes, ASTM A333 Low Temperature Tubes Up To 24” Available for Immediate Supply at best price in India. ASTM A333 alloy pipe shall be made by the seamless or welding process with the addition of no filler metal in the welding operation. All seamless and welded pipes shall be treated to control their microstructure.

ASTM A333 Grade 1 Pipe /ASME SA333 Grade 1 Carbon Steel Seamless Pipes

ASTM A333 Grade 1 seamless and welded carbon and alloy steel pipe intended for use at low temperatures.

ASTM A333 Grade 1 seamless and welded carbon and alloy steel pipe intended for use at low temperatures.

ASTM A333 Grade 1 Pipe, ASTM A333 Grade 1 Tubes, ASTM A333 Grade 1 seamless and welded pipes shall be treated to control their microstructure. Tensile tests, impact tests, hydrostatic tests, and nondestructive electric tests shall be made in accordance to specified requirements.

Astm A333 Grade 3 Pipe /asme Sa333 Grade 3 Carbon Steel Seamless Pipes

ASTM A333 Grade 1 seamless and welded carbon and alloy steel pipe intended for use at low temperatures.

ASTM A333 Grade 1 seamless and welded carbon and alloy steel pipe intended for use at low temperatures.

- ASTM A333 Grade 3 is the part of standard covers wall seamless and welded carbon and alloy steel pipe intended for use at low temperatures. ASTM A333 Grade 3 alloy pipe shall be made by the seamless or welding process with the addition of no filler metal in the welding operation.

- ASTM A333 Grade 3 seamless and welded carbon and alloy steel pipe intended for use at low temperatures.

- ASMT A333 Grade 3 seamless and welded pipes shall be treated to control their microstructure. Tensile tests, impact tests, hydrostatic tests, and nondestructive electric tests shall be made in accordance to specified requirements.

Astm A333 Grade 4 Pipe /asme Sa333 Grade 4 Carbon Steel Seamless Pipes

- ASTM A333 Grade 4 is the part of standard covers wall seamless and welded carbon and alloy steel pipe intended for use at low temperatures. ASTM A333 Grade 4 alloy pipe shall be made by the seamless or welding process with the addition of no filler metal in the welding operation.

- ASTM A333 Grade 4 seamless and welded carbon and alloy steel pipe intended for use at low temperatures.

- ASMT A333 Grade 4 seamless and welded pipes shall be treated to control their microstructure. Tensile tests, impact tests, hydrostatic tests, and nondestructive electric tests shall be made in accordance to specified requirements.

Astm A333 Grade 6 Pipe /asme Sa333 Grade 6 Carbon Steel Seamless Pipes

This specification covers seamless and welded steel pipe for low temperature service. The Grade 6 alloy steel Pipe involved is similar to AISI 4032 low alloy steel.

This specification covers seamless and welded steel pipe for low temperature service. The Grade 6 alloy steel Pipe involved is similar to AISI 4032 low alloy steel.

Minimum Impact Test Temperature -45 C(-50 F)

Astm A333 Grade 7 Pipe /asme Sa333 Grade 7 Carbon Steel Seamless Pipes

- ASTM A333 Standard covers seamless and welded steel pipe for low temperature service. The Grade 7 steel involved is similar to AISI 4032 low alloy steel. ASTM A333 Grade 7 pipe shall be made by the seamless or welding process with the addition of no filler metal in the welding operation.

- Application: Seamless and Welded Steel Pipe for Low-Temperature Service.

- Steel grade: ASTM A333 Grade 7

- Minimum Impact Test Temperature -45 C(-50 F)

Astm A333 Grade 8 Pipe /asme Sa333 Grade 8 Carbon Steel Seamless Pipes

- ASTM A333 Standard covers seamless and welded steel pipe for low temperature service. The Grade 8 steel involved is similar to AISI 4032 low alloy steel. ASTM A333 Grade 8 pipe shall be made by the seamless or welding process with the addition of no filler metal in the welding operation.

- Minimum Impact Test Temperature -45 C(-50 F)

- ASTM A333 Grade 8 Machinability is good, similar to law alloy 4032 steel.

Astm A333 Grade 9 Pipe /asme Sa333 Grade 9 Carbon Steel Seamless Pipes

- ASTM A333 Grade 9 is the part of standard covers wall seamless and welded carbon and alloy steel pipe intended for use at low temperatures. ASTM A333 Grade 9 alloy pipe shall be made by the seamless or welding process with the addition of no filler metal in the welding operation.

- ASTM A333 Grade 9 seamless and welded carbon and alloy steel pipe intended for use at low temperatures.

- ASMT A333 Grade 9 seamless and welded pipes shall be treated to control their microstructure. Tensile tests, impact tests, hydrostatic tests, and nondestructive electric tests shall be made in accordance to specified requirements.

Astm A333 Grade 10 Pipe /asme Sa333 Grade 10 Carbon Steel Seamless Pipes

- ASTM A333 Grade 10 is the part of standard covers wall seamless and welded carbon and alloy steel pipe intended for use at low temperatures. ASTM A333 Grade 10 alloy pipe shall be made by the seamless or welding process with the addition of no filler metal in the welding operation.

- ASTM A333 Grade 10 seamless and welded carbon and alloy steel pipe intended for use at low temperatures.

- ASMT A333 Grade 10 seamless and welded pipes shall be treated to control their microstructure. Tensile tests, impact tests, hydrostatic tests, and nondestructive electric tests shall be made in accordance to specified requirements.

Astm A333 Grade 11 Pipe /asme Sa333 Grade 11 Carbon Steel Seamless Pipes

ASTM A333 Grade 11 is the part of standard covers wall seamless and welded carbon and alloy steel pipe intended for use at low temperatures. ASTM A333 Grade 11 alloy pipe shall be made by the seamless or welding process with the addition of no filler metal in the welding operation.

ASTM A333 Grade 11 is the part of standard covers wall seamless and welded carbon and alloy steel pipe intended for use at low temperatures. ASTM A333 Grade 11 alloy pipe shall be made by the seamless or welding process with the addition of no filler metal in the welding operation.

ASTM A333 Pipe, ASME SA333 Pipe, Astm A333 Seamless Pipes Specifications

| High Temperature Seamless Pipe | ASTM A333 Gr. B/C, API 5L Gr. B, ASTM A53 Gr. B |

|---|---|

| Heat Exchanger Seamless Tube | ASTM A333 |

| Low Temperature Seamless Pipe | ASTM A333 Gr. 3/6 |

| Low Temperature Seamless Tube | ASTM A334 Gr. 6 |

| High Yield Seamless Pipe | API 5L Gr. X42/X46/X52/X56/X60/X65/X70/X80 PSL-1/PSL-2 |

| High Yield Seamless Pipe | ISO 3183 Gr.L245, L290, L320, L360, L390, L415, L450, L485 |

| Atmospheric & Low Temp EFW Pipes | ASTM A671 Gr. CC60/CC65/CC70 |

| High Pressure & Moderate Temp EFW Pipes | ASTM A672 Gr. B60/B65/B70/C55/C60/C65/C70 |

| High Yield ERW/SAW Pipe | API 5L Gr. X42/X46/X52/X56/X60/X65/X70/X80 PSL-1/PSL-2 |

| High Yield ERW/SAW Pipe | ISO 3183 Gr.L245, L290, L320, L360, L390, L415, L450, L485 |

A333 Grade 1, 3, 4, 6, 7, 8, 9, 10 & 11 (Low Temperature Carbon Steel Seamless Pipe)

- Size Range : 4" to 26"

- Schedules :20, 30, 40, Standard (STD), Extra Heavy (XH), 80, 100, 120, 140, 160, XXH & heavier

- Grades: A333 Grade 1, A333 Grade 3, A333 Grade 4, A333 Grade 6, A333 Grade 7, A333 Grade 8, A333 Grade 9, A333 Grade 10, A333 Grade 11 Seamless Pipes

- Applications: Oil Refineries, Petrochemicals, Power Generation (Nuclear/Thermal), Steel, Sugar, Boiler Equipments, Pressure Vessels and General Engineering Purposes

End Connections for Line Pipes: Plain, Bevel, Screwed, Threaded

Type: ERW / Welded / Fabricated / CDW

Form: Round Pipes/Tubes, Square Pipes/Tubes, Rectangular Pipe/Tubes, Coiled Tubes, “U” Shape, Pan Cake Coils, Hydraulic Tubes

Length: Single Random, Double Random & Required Length, Custom Size – 12 Meter lengths

End: Plain End, Beveled End, Treaded

End Protection: Plastic Caps

Outside Coating: Black Painting, Anti-Corrosion Oil, Galvanised Finish, Finish as per customer Requirements

Delivery Condition: Annealed, Normalized, Normalized and Tempered

Inspection, Test Reports: Chemical Composition inspection, Mechanical Properties Test(Tensile Strength, Yield Strength, Elongation, Flaring, Flattening, Hardness, Impact Test), Surface and Dimension Test, No-destructive Test, Hydrostatic Test

Note:

- Mill test certificates will be issued according to EN10204.3

- All tubes shall be supplied as per applicable ASTM Specification.

- The tubes Shall be Seamless and the testing shall be as per A 450 / A450M.

Price List of ASTM A333 Pipe, ASME SA333 Pipe Price, astm a333 grade 3 pipe, astm a333 grade 1 pipe Price

- astm a333 grade 3 seamless pipe

US $520-650 / Ton (FOB Price) - astm a333 grade 3

US $360-420 / Ton (FOB Price) - ASTM A333 Grade 6 Seamless Steel Pipe

US $470-680 / Ton (FOB Price) - ASTM A333 Grade 1 Seamless Pipes

US $500-1000 / Ton (FOB Price) - astm a333 grade 1 pipe

US $450-550 / Ton (FOB Price) - ASTM A333 Grade 6 Seamless Pipe

US $2003-3503 / Ton (FOB Price) - astm a333 grade 6 carbon steel casing pipe

US $600-900 / Ton (FOB Price) - Astm A333 Grade 3 Low Temperature Pipe

US $450.0-700.0 / Tons (FOB Price) - ASTM A333 Grade 3 Seamless Steel Pipe

US $450-550 / Ton (FOB Price) - astm a333 grade 6 gr6 low temperature pipe

US $400-1000 / Metric Ton (FOB Price) - astm a333 grade 6 pipe

US $1-1000 / Ton (FOB Price) - ASTM A333 Grade 3 boiler tube

US $550-850 / Ton (FOB Price) - ASTM A333 Grade 3 Seamless pipe

US $500-1000 / Ton (FOB Price) - ASTM A333 Grade 3 Low Temperature Carbon Steel Pipes

US $599-899 / Metric Ton (FOB Price) - ASTM A333 Grade 1 Seamless Steel Pipe

US $359-559 / Ton (FOB Price) - astm a333 gr.1 low temperature seamless pipe

US $500-1000 / Ton (FOB Price) - astm a333 grade 1 pipe

US $600-1000 / Ton (FOB Price) - ASTM A333 grade 1 seamless steel pipes

US $500-1500 / Ton (FOB Price)

ASTM A333 Pipe, ASME SA333 Pipe Stock

dimensions of ASTM A333 Pipe, ASME SA333 Pipe

| Carbon Steel Welded and seamless pipe

1/2 to 6 NPS | Dimensions and weights section modulus and gallons capacity per linear foot |

| Size NPS | Pipe O.D. | Wall Thickness | Pipe I.D. | Weight per Foot | Standard to XXHY | Schedule Pipe # | Section Modulus | Gallon Capacity Per Linear Foot |

|---|---|---|---|---|---|---|---|---|

| 1/2 | 0.84 | 0.109 | 0.622 | 0.85 | STD | 40 | .0407 | .0158 |

| 0.147 | 0.546 | 1.09 | XHY | 80 | .0478 | .0122 | ||

| 0.188 | 0.464 | 1.31 | 160 | .0528 | .0088 | |||

| 0.294 | 0.252 | 1.72 | XXHY | .0577 | .0026 | |||

| 3/4 | 1.05 | 0.113 | 0.824 | 1.13 | STD | 40 | .0705 | .0277 |

| 0.154 | 0.742 | 1.48 | XHY | 80 | .0853 | .0225 | ||

| 0.219 | 0.612 | 1.95 | 160 | .1006 | .0153 | |||

| 0.308 | 0.434 | 2.44 | XXHY | .1103 | .0077 | |||

| 1 | 1.315 | 0.133 | 1.049 | 1.68 | STD | 40 | .1328 | .0449 |

| 0.179 | 0.957 | 2.17 | XHY | 80 | .1606 | .0374 | ||

| 0.250 | 0.815 | 2.85 | 160 | .1904 | .0271 | |||

| 0.358 | 0.599 | 3.66 | XXHY | .2136 | .0146 | |||

| 1 1/4 | 1.66 | 0.140 | 1.380 | 2.27 | STD | 40 | .2346 | .0777 |

| 0.191 | 1.278 | 3.00 | XHY | 80 | .2913 | .0666 | ||

| 0.250 | 1.160 | 3.77 | 160 | .3421 | .0549 | |||

| 0.382 | 0.896 | 5.22 | .4110 | .0328 | ||||

| 1 1/2 | 1.90 | 0.145 | 1.610 | 2.72 | STD | 40 | .3262 | .1058 |

| 0.200 | 1.500 | 3.63 | XHY | 80 | .4118 | .0918 | ||

| 0.281 | 1.338 | 4.86 | 160 | .5079 | .0730 | |||

| 0.400 | 1.100 | 6.41 | .5977 | .0494 | ||||

| 2 | 2.375 | 0.109 | 2.157 | 2.64 | 10 | .4205 | .1898 | |

| 0.154 | 2.067 | 3.66 | STD | 40 | .5606 | .1743 | ||

| 0.218 | 1.939 | 5.03 | XHY | 80 | .7309 | .1534 | ||

| 0.250 | 1.875 | 5.68 | .8045 | .1434 | ||||

| 0.281 | 1.813 | 6.29 | .8666 | .1344 | ||||

| 0.344 | 1.687 | 7.47 | 160 | .9806 | .1161 | |||

| 0.436 | 1.503 | 9.04 | XXHY | 1.1043 | .0922 | |||

| 2 1/2 | 2.875 | 0.120 | 2.635 | 3.53 | 10 | .6870 | .2833 | |

| 0.203 | 2.469 | 5.80 | STD. | 40 | 1.0640 | .2487 | ||

| 0.216 | 2.443 | 6.14 | 1.1169 | .2435 | ||||

| 0.250 | 2.375 | 7.02 | 1.2468 | .2301 | ||||

| 0.276 | 2.323 | 7.67 | XHY | 80 | 1.3386 | .2202 | ||

| 0.375 | 2.125 | 10.02 | 160 | 1.6371 | .1842 | |||

| 0.552 | 1.771 | 13.71 | XXXHY | 1.9971 | .1280 | |||

| 3 | 3.50 | 0.120 | 3.260 | 4.34 | 1.0411 | .4336 | ||

| 0.156 | 3.188 | 5.58 | 1.3122 | .4147 | ||||

| 0.172 | 3.156 | 6.12 | 1.4265 | .4064 | ||||

| 0.188 | 3.124 | 6.66 | 1.5342 | .3984 | ||||

| 0.216 | 3.068 | 7.58 | STD. | 40 | 1.7241 | .3840 | ||

| 0.250 | 3.000 | 8.69 | 1.9372 | .3672 | ||||

| 0.281 | 2.938 | 9.67 | 2.1207 | .3521 | ||||

| 0.300 | 2.900 | 10.26 | XHY | 80 | 2.2253 | .3431 | ||

| 0.438 | 2.624 | 14.34 | 160 | 2.8774 | .2811 | |||

| 0.600 | 2.300 | 18.6 | XXHY | 3.4243 | .2158 | |||

| 3 1/2 | 4.0 | 0.120 | 3.760 | 4.98 | 10 | 1.3776 | .5768 | |

| 0.226 | 3.548 | 9.12 | STD. | 140 | 2.3939 | .5136 | ||

| 0.250 | 3.500 | 10.02 | 2.6001 | .4998 | ||||

| 0.281 | 3.438 | 11.17 | 2.8562 | .4821 | ||||

| 0.318 | 3.364 | 12.52 | XHY | 80 | 3.1400 | .4617 | ||

| 0.636 | 2..728 | 22.87 | XXHY | 4.8795 | .3085 | |||

| 4 | 4.5 | 0.120 | 4.260 | 5.62 | 10 | 1.7612 | .7404 | |

| 0.156 | 4.188 | 7.24 | 2.2354 | .7156 | ||||

| 0.188 | 4.124 | 8.67 | 2.6296 | .6942 | ||||

| 0.203 | 4.094 | 9.32 | 2.8173 | .6838 | ||||

| 0.219 | 4.062 | 10.02 | 3.0184 | .6725 | ||||

| 0.237 | 4.026 | 10.80 | STD. | 40 | 3.2145 | .6613 | ||

| 0.250 | 4.000 | 11.36 | 3.3611 | .6528 | ||||

| 0.281 | 3.938 | 12.67 | 60 | 3.7021 | .6326 | |||

| 0.312 | 3.876 | 13.97 | 4.0273 | .6126 | ||||

| 0.337 | 3.826 | 15.00 | XHY | 80 | 4.2713 | .5972 | ||

| 0.438 | 3.624 | 19.02 | 120 | 5.1790 | .5361 | |||

| 0.531 | 3.438 | 22.53 | 160 | 5.8997 | .4822 | |||

| 0.674 | 3.152 | 27.57 | XXHY | 6.7927 | .4054 | |||

| 5 | 5.563 | 0.188 | 5.187 | 10.80 | 4.1161 | 1.0979 | ||

| 0.219 | 5.125 | 12.51 | 4.7279 | 1.0716 | ||||

| 0.258 | 5.047 | 14.63 | STD. | 40 | 5.4500 | 1.0391 | ||

| 0.281 | 5.001 | 15.87 | 5.8644 | 1.0204 | ||||

| 0.312 | 4.939 | 17.51 | 6.4074 | .99647 | ||||

| 0.344 | 4.875 | 19.19 | 6.9358 | .9696 | ||||

| 0.375 | 4.813 | 20.80 | XHY | 80 | 7.4300 | .9449 | ||

| 0.500 | 4.563 | 27.06 | 120 | 9.2534 | .8495 | |||

| 0.625 | 4.313 | 32.99 | 160 | 10.7976 | .7590 | |||

| 0.750 | 4.063 | 38.59 | XXHY | 12.0954 | .6734 | |||

| 6 | 6.625 | 0.109 | 6.407 | 7.59 | 5 | 3.5769 | 1.6748 | |

| 0.134 | 6.357 | 9.30 | 10 | 4.3475 | 1.6488 | |||

| 0.156 | 6.313 | 10.79 | 5.0107 | 1.6260 | ||||

| 0.188 | 6.249 | 12.94 | 5.9351 | 1.5937 | ||||

| 0.203 | 6.219 | 13.94 | 6.3804 | 1.5780 | ||||

| 0.219 | 6.187 | 15.00 | 6.8261 | 1.5620 | ||||

| 0.250 | 6.125 | 17.04 | 7.6905 | 1.5306 | ||||

| 0.280 | 6.065 | 18.99 | STD. | 40 | 8.4958 | 1.5008 | ||

| 0.312 | 6.001 | 21.06 | 9.3416 | 1.4688 | ||||

| 0.344 | 5.937 | 23.10 | 10.111 | 1.4391 | ||||

| 0.375 | 5.875 | 25.05 | 10.893 | 1.4082 | ||||

| 0.432 | 5.761 | 28.60 | XHY | 80 | 12.224 | 1.3541 | ||

| 0.500 | 5.625 | 32.74 | 13.711 | 1.2909 | ||||

| 0.562 | 5.501 | 36.43 | 120 | 14.9806 | 1.2346 | |||

| 0.625 | 5.375 | 40.09 | 16.1821 | 1.1787 | ||||

| 0.719 | 5.187 | 45.39 | 160 | 17.8243 | 1.0977 | |||

| 0.864 | 4.897 | 53.21 | XXHY | 20.025 | .9784 | |||

| 1.000 | 4.625 | 60.13 | 21.7719 | .8727 | ||||

| 1.125 | 4.375 | 66.14 | 23.1237 | .7809 |

are you looking for jsl make ASTM A333 Pipe, ASME SA333 Pipe, carbon steel pipe, carbon steel Tube Buy directly from dealer of jindal limited

|

|

ASTM A333 Pipe, ASME SA333 Pipe, ASTM A333 Seamless Steel Pipes, ASTM A333 Low Temperature Seamless Steel Tubes Chemical Composition

Chemical composition % | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Grade | 1 | 3 | 4 | 6 | 7 | 8 | 9 | 10 | 11 |

C,max | 0.3 | 0.19 | 0.12 | 0.3 | 0.19 | 0.13 | 0.2 | 0.2 | 0.1 |

Mn | 0.40-1.06 | 0.31-0.64 | 0.5-1.05 | 0.29-1.06 | 0.9,max | 0.9,max | 0.4-1.06 | 1.15-1.5 | 0.6,max |

P,max | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.035 | 0.025 |

S,max | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 |

Si | – | 0.18-0.37 | 0.08-0.37 | 0.1,min | 0.13-0.32 | 0.13-0.32 | … | 0.1-0.35 | 0.35,max |

Ni | – | 3.18-3.82 | 0.47-0.98 | – | 2.03-2.57 | 8.4-9.6 | 1.6-2.24 | 0.25,max | 35-37 |

Cr | – | – | 0.44-1.01 | – | – | – | – | 0.15,max | 0.5,max |

Cu | – | – | 0.4-0.75 | – | – | – | 0.75-1.25 | 0.15,max | – |

Al | – | – | 0.04-0.3 | – | – | – | – | 0.06,max | – |

V,max | – | – | – | – | – | – | – | 0.12 | – |

Nb,max | – | – | – | – | – | – | – | 0.05 | – |

Mo,max | – | – | – | – | – | – | – | 0.05 | 0.5,max |

Co | – | – | – | – | – | – | – | – | 0.5,max |

Mn | 0.40-1.06 | 0.31-0.64 | 0.5-1.05 | 0.29-1.06 | 0.9,max | 0.9,max | 0.4-1.06 | 1.15-1.5 | 0.6,max |

ASTM A333 Seamless Steel Pipes, ASTM A333 Pipe, ASME SA333 Pipe Yield And Tensile Strength

| Tensile Strength | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| GRADE | 1 | 3 | 4 | 6 | 7 | 8 | 9 | 10 | 11 |

| Tensile strength, min,Mpa | 380 | 450 | 415 | 415 | 450 | 690 | 435 | 550 | 450 |

| Yield strength, min,Mpa | 205 | 240 | 240 | 240 | 240 | 515 | 315 | 450 | 240 |

| Elongation,min, (s≥8mm) | 35% | 30% | 30% | 30% | 30% | 22% | 28% | 22% | 18% |

| Elongation, min, (Standard circle) | 28% | 22% | 22% | 22% | 22% | 16% | – | 16% | – |

| Elongation(s<8mm) Percentage reduction from basic each reduction of 8mm of wall thickness | 1.75 | 1.5 | 1.5 | 1.5 | 1.5 | 1.25 | 1.5 | 1.25 | – |

ASTM A333 Pipe, ASME SA333 Pipe Strike Temperature Condition

| Crade | The lowest temperature for strike test | |

|---|---|---|

| ℉ | ℃ | |

| Grade 1 | -50 | -45 |

| Grade 3 | -150 | -100 |

| Grade 4 | -150 | -100 |

| Grade 6 | -50 | -45 |

| Grade 7 | -100 | -75 |

| Grade 8 | -320 | -195 |

| Grade 9 | -100 | -75 |

| Grade 10 | -75 | -60 |

ASTM A333 Pipe, ASME SA333 Pipe Equivalent

| Grade | Pipe | Tube | Fittings | Flanges | Bar | Forgings | EN | Material |

|---|---|---|---|---|---|---|---|---|

| Low Temp C.S. Gr. 1 | A333 GR. 1 | A333 GR. 1 | A420 WPL1/6 | A350 LF2 | A516 | A350 LF2 | ||

| Low Temp C.S. Gr. 3 | A333 GR. 3 | A333 GR. 3 | A420 WPL3 | A350 L3 | A516 | A350 LF3 | ||

| Low Temp C.S. Gr. 6 | A333 GR. 6 | A333 GR. 6 | A420 WPL6 | A350 LF2 | A516 | A350 LF2 | EN 10216-4 | P265NL |

Pressure Temperature Rating of ASTM A333 Pipe, ASME SA333 Pipe

ASTM A333 Grade 6 Carbon Steel Pipes – Pressure (psig) and temperature (deg F) ratings for A-53 B and A-106 B, A333, A334 and API 5L carbon steel pipes – temperatures ranging 100 °F – 700 °F

Ratings calculated (see below the table) according ASME B31.3-2002 Table K-1 for plain end standard seamless carbon steel pipes and tubes spec. no. A-53 B, A-106 B, A333, A334 and API 5L. Temperatures ranging 100 °F – 700 °F.

| Size (in) | Outside Diameter (in) | Wall Thickness (in) | Inside Diameter (in) | Schedule | Temperature (oF) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 100 | 200 | 300 | 400 | 500 | 600 | 650 | 700 | |||||

| Allowable Stress (psi) | ||||||||||||

| 23300 | 21300 | 20700 | 20000 | 18900 | 17300 | 16900 | 16800 | |||||

| Maximum Allowable Pressure (psi) | ||||||||||||

| 1/2 | 0.84 | 0.109 | 0.622 | 401) | 6747 | 6168 | 5994 | 5792 | 5473 | 5010 | 4894 | 4865 |

| 0.84 | 0.147 | 0.546 | 802) | 9483 | 8669 | 8424 | 8140 | 7692 | 7041 | 6878 | 6837 | |

| 0.84 | 0.188 | 0.464 | 160 | 12704 | 11614 | 11287 | 10905 | 10305 | 9433 | 9215 | 9160 | |

| 0.84 | 0.294 | 0.252 | 22653 | 20708 | 20125 | 19444 | 18375 | 16819 | 16431 | 16333 | ||

| 3/4 | 1.05 | 0.113 | 0.824 | 40 | 5487 | 5016 | 4875 | 4710 | 4451 | 4074 | 3980 | 3957 |

| 1.05 | 0.154 | 0.742 | 80 | 7743 | 7079 | 6879 | 6647 | 6281 | 5749 | 5616 | 5583 | |

| 1.05 | 0.219 | 0.612 | 160 | 11666 | 10665 | 10364 | 10014 | 9463 | 8662 | 8462 | 8412 | |

| 1.05 | 0.308 | 0.434 | 17861 | 16328 | 15868 | 15331 | 14488 | 13261 | 12955 | 12878 | ||

| 1 | 1.315 | 0.133 | 1.049 | 40 | 5128 | 4688 | 4556 | 4402 | 4160 | 3808 | 3720 | 3698 |

| 1.315 | 0.179 | 0.957 | 80 | 7118 | 6507 | 6324 | 6110 | 5774 | 5285 | 5163 | 5133 | |

| 1.315 | 0.25 | 0.815 | 160 | 10448 | 9552 | 9283 | 8969 | 8475 | 7758 | 7578 | 7534 | |

| 1.315 | 0.358 | 0.599 | 16219 | 14827 | 14409 | 13922 | 13156 | 12042 | 11764 | 11694 | ||

| 1 1/4 | 1.66 | 0.14 | 1.38 | 40 | 4214 | 3853 | 3744 | 3618 | 3419 | 3129 | 3057 | 3039 |

| 1.66 | 0.191 | 1.278 | 80 | 5905 | 5398 | 5246 | 5069 | 4790 | 4385 | 4283 | 4258 | |

| 1.66 | 0.25 | 1.16 | 160 | 7979 | 7295 | 7089 | 6849 | 6473 | 5925 | 5788 | 5753 | |

| 1.66 | 0.382 | 0.896 | 13143 | 12015 | 11677 | 11282 | 10661 | 9759 | 9533 | 9477 | ||

| 1 1/2 | 1.9 | 0.145 | 1.61 | 40 | 3788 | 3462 | 3365 | 3251 | 3072 | 2812 | 2747 | 2731 |

| 1.9 | 0.2 | 1.5 | 80 | 5356 | 4897 | 4759 | 4598 | 4345 | 3977 | 3885 | 3862 | |

| 1.9 | 0.281 | 1.338 | 160 | 7817 | 7146 | 6944 | 6710 | 6341 | 5804 | 5670 | 5636 | |

| 1.9 | 0.4 | 1.1 | 11797 | 10785 | 10481 | 10127 | 9570 | 8759 | 8557 | 8506 | ||

| 2 | 2.375 | 0.109 | 2.157 | 10 | 2220 | 2030 | 1972 | 1906 | 1801 | 1648 | 1610 | 1601 |

| 2.375 | 0.154 | 2.067 | 40 | 3187 | 2913 | 2831 | 2736 | 2585 | 2366 | 2312 | 2298 | |

| 2.375 | 0.218 | 1.939 | 80 | 4616 | 4220 | 4101 | 3963 | 3745 | 3428 | 3348 | 3329 | |

| 2.375 | 0.25 | 1.875 | 5356 | 4897 | 4759 | 4598 | 4345 | 3977 | 3885 | 3862 | ||

| 2.375 | 0.281 | 1.813 | 6090 | 5567 | 5410 | 5227 | 4940 | 4522 | 4417 | 4391 | ||

| 2.375 | 0.344 | 1.687 | 160 | 7634 | 6979 | 6782 | 6553 | 6193 | 5668 | 5537 | 5505 | |

| 2.375 | 0.436 | 1.503 | 10027 | 9167 | 8908 | 8607 | 8134 | 7445 | 7273 | 7230 | ||

| 2 1/2 | 2.875 | 0.12 | 2.635 | 10 | 2012 | 1840 | 1788 | 1727 | 1632 | 1494 | 1460 | 1451 |

| 2.875 | 0.203 | 2.469 | 40 | 3487 | 3188 | 3098 | 2993 | 2829 | 2589 | 2529 | 2514 | |

| 2.875 | 0.216 | 2.443 | 3725 | 3405 | 3309 | 3197 | 3022 | 2766 | 2702 | 2686 | ||

| 2.875 | 0.25 | 2.375 | 4355 | 3981 | 3869 | 3738 | 3533 | 3234 | 3159 | 3140 | ||

| 2.875 | 0.276 | 2.323 | 80 | 4846 | 4430 | 4305 | 4159 | 3931 | 3598 | 3515 | 3494 | |

| 2.875 | 0.375 | 2.125 | 160 | 6786 | 6204 | 6029 | 5825 | 5505 | 5039 | 4922 | 4893 | |

| 2.875 | 0.552 | 1.771 | 10571 | 9664 | 9391 | 9074 | 8575 | 7849 | 7667 | 7622 | ||

| 3 | 3.5 | 0.12 | 3.26 | 1643 | 1502 | 1459 | 1410 | 1333 | 1220 | 1192 | 1184 | |

| 3.5 | 0.156 | 3.188 | 2154 | 1969 | 1913 | 1849 | 1747 | 1599 | 1562 | 1553 | ||

| 3.5 | 0.172 | 3.156 | 2384 | 2179 | 2118 | 2046 | 1934 | 1770 | 1729 | 1719 | ||

| 3.5 | 0.188 | 3.124 | 2615 | 2391 | 2324 | 2245 | 2122 | 1942 | 1897 | 1886 | ||

| 3.5 | 0.216 | 3.068 | 40 | 3025 | 2766 | 2688 | 2597 | 2454 | 2246 | 2194 | 2181 | |

| 3.5 | 0.25 | 3 | 3530 | 3227 | 3136 | 3030 | 2864 | 2621 | 2561 | 2545 | ||

| 3.5 | 0.281 | 2.938 | 3998 | 3655 | 3552 | 3432 | 3243 | 2969 | 2900 | 2883 | ||

| 3.5 | 0.3 | 2.9 | 80 | 4288 | 3920 | 3810 | 3681 | 3479 | 3184 | 3110 | 3092 | |

| 3.5 | 0.438 | 2.624 | 160 | 6480 | 5924 | 5757 | 5563 | 5257 | 4812 | 4700 | 4673 | |

| 3.5 | 0.6 | 2.3 | 9258 | 8464 | 8225 | 7947 | 7510 | 6874 | 6715 | 6675 | ||

| 3 1/2 | 4 | 0.12 | 3.76 | 10 | 1432 | 1309 | 1273 | 1230 | 1162 | 1064 | 1039 | 1033 |

| 4 | 0.226 | 3.548 | 140 | 2758 | 2521 | 2450 | 2367 | 2237 | 2047 | 2000 | 1988 | |

| 4 | 0.25 | 3.5 | 3066 | 2803 | 2724 | 2632 | 2487 | 2276 | 2224 | 2211 | ||

| 4 | 0.281 | 3.438 | 3469 | 3171 | 3082 | 2977 | 2814 | 2575 | 2516 | 2501 | ||

| 4 | 0.318 | 3.364 | 80 | 3956 | 3617 | 3515 | 3396 | 3209 | 2938 | 2870 | 2853 | |

| 4 | 0.636 | 2..728 | 8489 | 7761 | 7542 | 7287 | 6886 | 6303 | 6157 | 6121 | ||

| 4 | 4.5 | 0.12 | 4.26 | 10 | 1270 | 1161 | 1128 | 1090 | 1030 | 943 | 921 | 916 |

| 4.5 | 0.156 | 4.188 | 1662 | 1519 | 1476 | 1426 | 1348 | 1234 | 1205 | 1198 | ||

| 4.5 | 0.188 | 4.124 | 2014 | 1841 | 1789 | 1729 | 1634 | 1495 | 1461 | 1452 | ||

| 4.5 | 0.203 | 4.094 | 2181 | 1994 | 1938 | 1872 | 1769 | 1619 | 1582 | 1572 | ||

| 4.5 | 0.219 | 4.062 | 2360 | 2157 | 2096 | 2026 | 1914 | 1752 | 1712 | 1701 | ||

| 4.5 | 0.237 | 4.026 | 40 | 2562 | 2342 | 2276 | 2199 | 2078 | 1902 | 1858 | 1847 | |

| 4.5 | 0.25 | 4 | 2709 | 2477 | 2407 | 2326 | 2198 | 2012 | 1965 | 1953 | ||

| 4.5 | 0.281 | 3.938 | 60 | 3063 | 2800 | 2721 | 2629 | 2485 | 2274 | 2222 | 2208 | |

| 4.5 | 0.312 | 3.876 | 3421 | 3127 | 3039 | 2936 | 2775 | 2540 | 2481 | 2466 | ||

| 4.5 | 0.337 | 3.826 | 80 | 3712 | 3394 | 3298 | 3186 | 3011 | 2756 | 2693 | 2677 | |

| 4.5 | 0.438 | 3.624 | 120 | 4919 | 4497 | 4370 | 4222 | 3990 | 3652 | 3568 | 3547 | |

| 4.5 | 0.531 | 3.438 | 160 | 6072 | 5551 | 5394 | 5212 | 4925 | 4508 | 4404 | 4378 | |

| 4.5 | 0.674 | 3.152 | 7930 | 7249 | 7045 | 6807 | 6432 | 5888 | 5752 | 5718 | ||

| 5 | 5.563 | 0.188 | 5.187 | 1619 | 1480 | 1438 | 1389 | 1313 | 1202 | 1174 | 1167 | |

| 5.563 | 0.219 | 5.125 | 1894 | 1732 | 1683 | 1626 | 1536 | 1406 | 1374 | 1366 | ||

| 5.563 | 0.258 | 5.047 | 40 | 2244 | 2052 | 1994 | 1927 | 1821 | 1667 | 1628 | 1618 | |

| 5.563 | 0.281 | 5.001 | 2453 | 2242 | 2179 | 2106 | 1990 | 1821 | 1779 | 1769 | ||

| 5.563 | 0.312 | 4.939 | 2736 | 2501 | 2431 | 2349 | 2220 | 2032 | 1985 | 1973 | ||

| 5.563 | 0.344 | 4.875 | 3032 | 2771 | 2693 | 2602 | 2459 | 2251 | 2199 | 2186 | ||

| 5.563 | 0.375 | 4.813 | 80 | 3320 | 3035 | 2950 | 2850 | 2693 | 2465 | 2408 | 2394 | |

| 5.563 | 0.5 | 4.563 | 120 | 4513 | 4126 | 4009 | 3874 | 3661 | 3351 | 3273 | 3254 | |

| 5.563 | 0.625 | 4.313 | 160 | 5753 | 5259 | 5111 | 4938 | 4666 | 4271 | 4172 | 4148 | |

| 5.563 | 0.75 | 4.063 | 7042 | 6438 | 6256 | 6045 | 5712 | 5229 | 5108 | 5078 | ||

ASTM A333 Pipe, ASME SA333 PipeSchedule Chart & Wall Thickness

Nominal wall thickness for ASTM A333 Grade 6 Carbon Steel Seamless Pipe/ ASTM A333 seamless and welded steel pipes according ANSI B36.10:

| NPS (in) | Outside Diameter (in) | ASTM A333 Grade 6 Carbon Steel Seamless Pipe Schedule | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SCH 10 | SCH 20 | SCH 30 | SCH STD | SCH 40 | SCH 60 | SCH XS | SCH 80 | SCH 100 | SCH 120 | SCH 140 | SCH 160 | SCH XXS | ||

| Wall Thickness (in) | ||||||||||||||

| 1/8 | 0.405 | 0.068 | 0.068 | 0.095 | 0.095 | |||||||||

| 1/4 | 0.540 | 0.088 | 0.088 | 0.119 | 0.119 | |||||||||

| 3/8 | 0.675 | 0.091 | 0.091 | 0.126 | 0.126 | |||||||||

| 1/2 | 0.840 | 0.109 | 0.109 | 0.147 | 0.147 | 0.187 | 0.294 | |||||||

| 3/4 | 1.050 | 0.113 | 0.113 | 0.154 | 0.154 | 0.219 | 0.308 | |||||||

| 1 | 1.315 | 0.133 | 0.133 | 0.179 | 0.179 | 0.250 | 0.358 | |||||||

| 1 1/4 | 1.660 | 0.140 | 0.140 | 0.191 | 0.191 | 0.250 | 0.382 | |||||||

| 1 1/2 | 1.900 | 0.145 | 0.145 | 0.200 | 0.200 | 0.281 | 0.400 | |||||||

| 2 | 2.375 | 0.154 | 0.154 | 0.218 | 0.218 | 0.344 | 0.436 | |||||||

| 2 1/2 | 2.875 | 0.203 | 0.203 | 0.276 | 0.276 | 0.375 | 0.552 | |||||||

| 3 | 3.500 | 0.216 | 0.216 | 0.300 | 0.300 | 0.438 | 0.600 | |||||||

| 3 1/2 | 4.000 | 0.226 | 0.226 | 0.318 | 0.318 | |||||||||

| 4 | 4.500 | 0.237 | 0.237 | 0.337 | 0.337 | 0.438 | 0.531 | 0.674 | ||||||

| 5 | 5.563 | 0.258 | 0.258 | 0.375 | 0.375 | 0.500 | 0.625 | 0.750 | ||||||

| 6 | 6.625 | 0.280 | 0.280 | 0.432 | 0.432 | 0.562 | 0.719 | 0.864 | ||||||

| 8 | 8.625 | 0.250 | 0.277 | 0.322 | 0.322 | 0.406 | 0.500 | 0.500 | 0.594 | 0.719 | 0.812 | 0.906 | 0.875 | |

| 10 | 10.750 | 0.250 | 0.307 | 0.365 | 0.365 | 0.500 | 0.500 | 0.594 | 0.719 | 0.844 | 1.000 | 1.125 | 1.000 | |

| 12 | 12.750 | 0.250 | 0.330 | 0.375 | 0.406 | 0.562 | 0.500 | 0.688 | 0.844 | 1.000 | 1.125 | 1.312 | 1.000 | |

| 14 | 14.000 | 0.250 | 0.312 | 0.375 | 0.375 | 0.438 | 0.594 | 0.500 | 0.750 | 0.938 | 1.094 | 1.250 | 1.406 | |

| 16 | 16.000 | 0.250 | 0.312 | 0.375 | 0.375 | 0.500 | 0.656 | 0.500 | 0.844 | 1.031 | 1.219 | 1.438 | 1.594 | |

| 18 | 18.000 | 0.250 | 0.312 | 0.438 | 0.375 | 0.562 | 0.750 | 0.500 | 0.938 | 1.156 | 1.375 | 1.562 | 1.781 | |

| 20 | 20.000 | 0.250 | 0.375 | 0.500 | 0.375 | 0.594 | 0.812 | 0.500 | 1.031 | 1.281 | 1.500 | 1.750 | 1.969 | |

| 22 | 22.000 | 0.250 | 0.375 | 0.500 | 0.375 | 0.875 | 0.500 | 1.125 | 1.375 | 1.625 | 1.875 | 2.125 | ||

| 24 | 24.000 | 0.250 | 0.375 | 0.562 | 0.375 | 0.688 | 0.969 | 0.500 | 1.219 | 1.531 | 1.812 | 2.062 | 2.344 | |

| 30 | 30.000 | 0.312 | 0.500 | 0.625 | 0.375 | 0.500 | ||||||||

| 32 | 32.000 | 0.312 | 0.500 | 0.625 | 0.375 | 0.688 | ||||||||

| 34 | 34.000 | 0.312 | 0.500 | 0.625 | 0.375 | 0.688 | ||||||||

| 36 | 36.000 | 0.312 | 0.500 | 0.625 | 0.375 | 0.750 | ||||||||

| 42 | 42.000 | 0.500 | 0.625 | 0.375 | 0.750 | |||||||||

ASTM A333 Pipe, ASME SA333 Pipe Wall Thickness & Tolerance

Outside Diameter, inch | Tolerance, % |

|---|---|

1/8≤OD≤2-1/2 | +20.0/-12.5 |

3≤OD≤18, WT/OD≤5% | +22.5/-12.5 |

3≤OD≤18, WT/OD>5% | +15.0/-12.5 |

OD≥20, WT/OD≤5% | +22.5/-12.5 |

OD≥20, WT/OD>5% | +15.0/-12.5 |

ASTM A333 Pipe, ASME SA333 Pipe Mechanical Properities:

| Grade 1 | |

|---|---|

| Minimum Yield | 30,000 PSI |

| Minimum Tensile | 55,000 PSI |

| Grade 3 | |

| Minimum Yield | 35,000 PSI |

| Minimum Tensile | 65,000 PSI |

| Grade 6 | |

| Minimum Yield | 35,000 PSI |

| Minimum Tensile | 60,000 PSI |

Tensile Requirements - ASTM A333 Pipe, ASME SA333 Pipe

| Data | ASTM A333 Grade 6 |

|---|---|

| Tensile strength, min, psi (MPa) | 60 000 (415) |

| Yield strength, min, psi (MPa) | 35 000 (240) |

Impact Temperature - ASTM A333 Pipe, ASME SA333 Pipe

| Size | Minimum Average Notched Bar Impact Value of Each Set of Three Specimens | Minimum Notched Bar Impact Value of One Specimen Only of a Set | ||

|---|---|---|---|---|

| Size of Specimen, mm | ft-lbf | J | ft-lbf | J |

| 10 by 10 | 13 | 18 | 10 | 14 |

| 10 by 7.5 | 10 | 14 | 8 | 11 |

| 10 by 6.67 | 9 | 12 | 7 | 9 |

| 10 by 5 | 7 | 9 | 5 | 7 |

| 10 by 3.33 | 5 | 7 | 3 | 4 |

| 10 by 2.5 | 4 | 5 | 3 | 4 |

Impact temperature reduction - ASTM A333 Pipe, ASME SA333 Pipe

| Specimen Width Along Notch or Actual Material Thickness mm | Temperature Reduction,Degrees Colder C |

|---|---|

| 10 (standard size) | 0 |

| 9 | 0 |

| 8 | 0 |

| 7.5 (3/4 standard size) | 3 |

| 7 | 4 |

| 6.67 (2/3 standard size) | 5 |

| 6 | 8 |

| 5 (1/2 standard size) | 11 |

| 4 | 17 |

| 3.33 (1/3 standard size) | 19 |

| 3 | 22 |

| 2.5 (1/4 standard size) | 28 |

P Number/ Group Number - ASTM A333 Pipe, ASME SA333 Pipe

ASTM A333 | Grade 6 |

|---|---|

| P Number | 1 |

| Group | 1 |

Length: Single Random, Double Random & Required Length, Custom Size – 12 Meter lengths

End: Plain End, Beveled End, Treaded

End Protection: Plastic Caps

Outside Coating: Black Painting, Anti-Corrosion Oil, Galvanised Finish, Finish as per customer Requirements

Inspection, Test Reports: Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports, India Boiler Regulations (IBR) Test Certificate

Packing: Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests

Specials: Sizes and Specifications other than above can be Supplier on request

ASTM A333 Pipe, ASME SA333 Pipe Grades, Size Range & carbon steel tubing specifications

| Pipe/ Tube Type | NB Sizes | Sch 5 | Sch 10 | Sch 40 | Sch 80 | Sch 160 |

|---|---|---|---|---|---|---|

| ASTM A333 Pipe, ASME SA333 Pipe | 1/2 | |||||

| ASTM A333 Pipe, ASME SA333 Pipe | 3/4 | |||||

| ASTM A333 Pipe, ASME SA333 Pipe | 1 | |||||

| ASTM A333 Pipe, ASME SA333 Pipe | 1.25 | |||||

| ASTM A333 Pipe, ASME SA333 Pipe | 1.5 | |||||

| ASTM A333 Pipe, ASME SA333 Pipe | 2 | |||||

| ASTM A333 Pipe, ASME SA333 Pipe | 2.5 | |||||

| ASTM A333 Pipe, ASME SA333 Pipe | 3 | |||||

| ASTM A333 Pipe, ASME SA333 Pipe | 3.5 | |||||

| ASTM A333 Pipe, ASME SA333 Pipe | 4 | |||||

| ASTM A333 Pipe, ASME SA333 Pipe | 5 | |||||

| ASTM A333 Pipe, ASME SA333 Pipe | 6 | |||||

| ASTM A333 Pipe, ASME SA333 Pipe | 8 | |||||

| ASTM A333 Pipe, ASME SA333 Pipe | 10 | |||||

| ASTM A333 Pipe, ASME SA333 Pipe | 12 | |||||

| ASTM A333 Pipe, ASME SA333 Pipe | 14 | |||||

| ASTM A333 Pipe, ASME SA333 Pipe | 16 | |||||

| ASTM A333 Pipe, ASME SA333 Pipe | 18 | |||||

| ASTM A333 Pipe, ASME SA333 Pipe | 20 | |||||

| ASTM A333 Pipe, ASME SA333 Pipe | 22 | |||||

| ASTM A333 Pipe, ASME SA333 Pipe | 24 |

Check Our Heavy Sale Products of ASTM A333 Pipe, ASME SA333 Pipe, ASTM A333 Low Temperature Tubing at most attractive price offer

Applications Of ASTM A333 Pipe, ASME SA333 Pipe In Seamless & Welded Form

- Refineries

- Power Plants

- Boilers

- Ship Building

- Heat Exchangers

- Condensers

- Paper & Pulp

- Marine Applications

- Nuclear Power

- Fossil Fuel Power Plants

ASTM A333 Pipe, ASME SA333 Pipe, ASTM A333 Low Temperature Tubing Packaging & Shipping

ASTM A333 Pipe, ASME SA333 Pipe, ASTM A333 Low Temperature Tubing in Seamless & Welded both are loose or in bundles tightened with Iron Strips. Special packings: Metal or Wooden Cases, Pallets etc. Plastic closes both ends, Hexagonal bundles maximum 2.000 kg with several steel strips, Two tags on each bundle, Wrapped in waterproof paper, PVC sleeve, and IN in sackcloth with several steel strips, Plastic caps.

Both ends of each crate will indicate the order no., heat no., dimensions, weight and bundles or as requested. We can also offer customized packaging for ASTM A333 Pipe, ASME SA333 Pipe, ASTM A333 Low Temperature Tubing as per customer's requirement.

Marking Requirements

Marking Requirements

Rolled, die stamped, or paint stenciled (manufacturer’s option).

- Manufacturer’s name, brand, or trademark

- ASTM A333 Pipe, ASME SA333 Pipe, ASTM A333 Low Temperature Tubing

- ANSI schedule number or weight class or wall thickness

- Additional “S” if tested supplementary requirements

- Hydrostatic test pressure and/or NDE, or NH if neither is specified

- Size, length, weight per foot (NPS 4 and larger)

Overseas Packaging

Export packaging is geared towards the protection, handling and transport of ASTM A333 Pipe, ASME SA333 Pipe, ASTM A333 Low Temperature Tubing by air or sea freight and, as such, shares many characteristics with export and transport packaging. Utmost care must also be taken to make overseas packaging suitable for long periods of storage. It is important for overseas packaging to be designed with ease of handling in mind, so as to ensure ASTM A333 Pipe, ASME SA333 Pipe, ASTM A333 Low Temperature Tubing is treated with the utmost care at all times.

Brands we Stock & Supply of ASTM A333 Pipe, ASME SA333 Pipe, ASTM A333 Low Temperature Tubing

Authorised Dealer & distributor of | ||||

|---|---|---|---|---|

United Seamless Limited -usl ASTM A333 Pipe, ASME SA333 Pipe |  Bao Steel- Bao ASTM A333 Pipe, ASME SA333 Pipe |  Yangzhou Lontrin Steel Tube -lontrin ASTM A333 Pipe, ASME SA333 Pipe |  Sumitomo Metals Smtm ASTM A333 Pipe, ASME SA333 Pipe |  Tenaris -tnrs ASTM A333 Pipe, ASME SA333 Pipe |

Valourec & Mannesman -v&m ASTM A333 Pipe, ASME SA333 Pipe |  Wuxi ASTM A333 Pipe, ASME SA333 Pipe |  Maharastra Seamless Limited -msl ASTM A333 Pipe, ASME SA333 Pipe |  Indian Seamless Metal Tubes Limited _ismt ASTM A333 Pipe, ASME SA333 Pipe |  Jindal Saw Ltd -jsl ASTM A333 Pipe, ASME SA333 Pipe |

We are approved vendor & Suppliers of ASTM A333 Pipe, ASME SA333 Pipe, ASTM A333 Low Temperature Tubing in GASCO, KNPC, SAUDI ARAMCO, SABIC, ORPIC, NIORDC, PIDMCO etc.

Vendor & Suppliers of | |||||

|---|---|---|---|---|---|

GASCO |  KNPC |  SAUDI ARAMCO |  SABIC |  ORPIC |  PIDMCO |

Mumbai | Thane | Navi Mumbai | Pune | Pimpri-Chinchwad | Vadodara | Kolkata | Gurgaon | Ahmedabad |

New Delhi | Bengaluru | Chennai | Surat | Bhopal | Ulsan | Faridabad | Houston | Dubai |

Seoul | Hyderabad | Singapore | Abu Dhabi | Tehran | Calgary | Noida | Riyadh | London |

Coimbatore | Jakarta | Istanbul | Bangkok | Kuwait City | Sharjah | Muscat | Edmonton | Edmonton |

Busan | Mexico City | Doha | Jeddah | Aberdeen | Cairo | Geoje-si | Perth | Santiago |

Chandigarh | Indore | Kuala Lumpur | Rio de Janeiro | Dammam | Melbourne | Madrid | La Victoria | Bogota |

Lahore | Los Angeles | Algiers | Chiyoda | Ankara | Ho Chi Minh City | Toronto | Hong Kong | Rajkot |

Brisbane | Petaling Jaya | Ernakulam | Secunderabad | Gimhae-si | Al Jubail | Port-of-Spain | Thiruvananthapuram | Milan |

Atyrau | Lagos | Hanoi | Howrah | Sydney | Ahvaz | Karachi | New York | Caracas |

Vung Tau | Al Khobar | Manama | Montreal | Granada | Courbevoie | Visakhapatnam | Ludhiana | Moscow |

Dallas | Haryana | Colombo |

India | Saudi Arabia | Bangladesh | United States | UAE | Canada | Angola | Argentina | Austria |

Azerbaijan | Pakistan | Peru | Chile | Spain | France | United Kingdom | Indonesia | Israel |

Iran | Kuwait | Mexico | Malaysia | Nigeria | Serbia | Singapore | Taiwan | Chile |

Venezuela | Ecuador | Netherlands | Brazil | Colombia | Ghana | Iran | Denmark | Poland |

Australia | Afghanistan | Bahrain | Costa Rica | Egypt | Iraq | Jordan | South Korea | Kazakhstan |

Sri Lanka | Lithuania | Norway | Oman | Philippines | Poland | Qatar | Russia | Vietnam |

South Africa | Nigeria | Mexico | Turkey | Hungary | Algeria | Belarus | Belgium | Bhutan |

Bolivia | Bulgaria | Croatia | Czech Republic | Estonia | Finland | Greece | Italy | Japan |

Libya | Romania | Thailand | Trinidad | Tobago | Tunisia | Ukraine | Yemen | Hong Kong |

Gabon | China | Portugal | Switzerland | New Zealand | Sweden | Slovakia | Kenya | Lebanon |

Morocco | Mongolia |