Worldwide Suppliers Of Alloy Steel T91 Seamless Pipes, T91 Seamless Tubes Exporters in India, Astm A213 T91, ASTM A213 T91 / ASME SA213 T91 Alloy Steel Seamless Tube, ASTM A213 Alloy Steel Tubes suppliers in India

ASTM A213 T91 Alloy Steel Seamless Tubes Suppliers In India, ASTM A213 Grade T91, ASTM A 213 Gr T91, A213 T91, ASTM A213 Gr T91, T91 material, A213 Chrome Moly Alloy heater tube Gr. T91, T91 high temperature tube, ASME SA213 Grade T91 Seamless Ferritic and Austenitic Alloy-Steel Boiler

Alloy Steel T91 Seamless Pipes Exports Is Our Specialty!!!!! IBR approved ASTM A213/ ASME SA213 T91 Alloy Steel Seamless Tube, ASTM A213/ASME SA213 Standard tubing / T91 alloy grade material tubing, ASTM A213 Grade T91 Alloy Steel Seamless Tube, ASTM A213 T91 High Pressure Steel Tube, T91 Steel Tubes

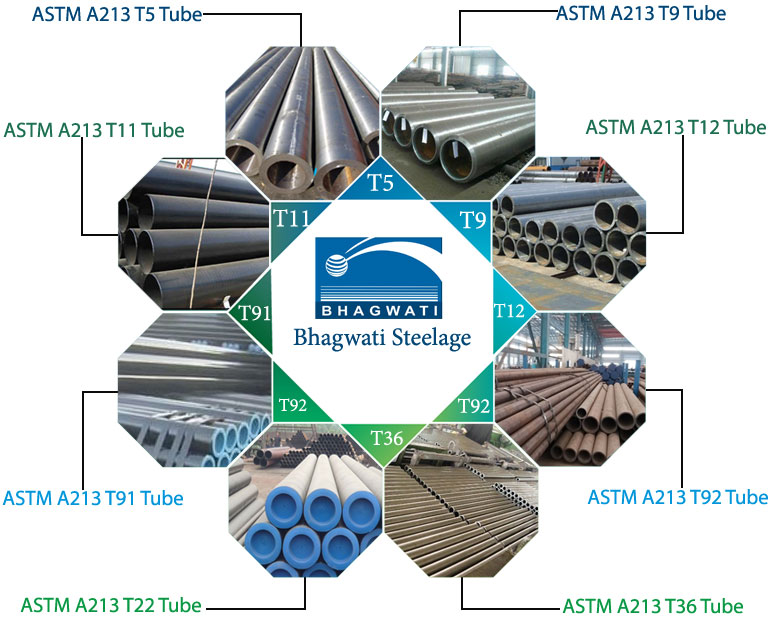

- ASTM A213 T1 Tube

- ASTM A213 T2 Tube

- ASTM A213 T5 Tube

- ASTM A213 T9 Tube

- ASTM A213 T11 Tube

- ASTM A213 T12 Tube

- ASTM A213 T17 Tube

- ASTM A213 T21 Tube

- ASTM A213 T22 Tube

- ASTM A213 T23 Tube

- ASTM A213 T24 Tube

- ASTM A213 T36 Tube

- ASTM A213 T91 Tube

- ASTM A213 T92 Tube

- ASTM A213 T122 Tube

- ASTM A213 T911 Tube

- ASME SA213 T5 Tube

- ASME SA213 T9 Tube

- ASME SA213 T91 Tube

- ASME SA213 T92 Tube

ASTM A213 T91 Tubes Manufacturers in India

“Request For Our Latest Prices” On Alloy Steel T91 Seamless Pipes And Tubes!!!

ASTM A213 T91 / ASME SA213 T91 Alloy Steel Seamless Tube Specifications

Material |

Size |

Sch. & Swg. |

Specification |

|

|---|---|---|---|---|

ASTM A213 T91 Seamless Tube |

6.35 mm OD To 101.6 mm OD |

10 Swg. 12 Swg. 14 Swg. 16 Swg. |

18 Swg. 20 Swg. 3.6 mm Thk |

ASTM A-213 & A-209 BS/3059/90/PartII/620 & 622 DIN/17175/13CrMo44 DIN/17175/10CrMo910 DIN/17175/15Mo3 |

Alloy Steel Tube in Grade |

ASTM A 213 – T-2, T-5, T-9, T-11, T-12, T-22, Etc. (with IBR Test Certificate) ASTM A 209 – T1 , Ta, T1b |

| Size (Seamless) | 6.35mm o.d to 101.60mm o.d |

| Standards | ASTM A213, ASME SA213 |

| Equivalent Standards | EN 10216-2, ASTM A335, GOST 550-75 |

| Material | T91, K90901 |

| Equivalent Material | X10CrMoVNb9-1, 1.4903, P91, K91560 |

| Type | Seamless |

| Specialized in | Large Diameter Size |

In Length of |

Single Random, Double Random & Required Length, Custom Size – 12 Meter lengths |

Value Added Service |

Draw & Expansion as per required Size & Length Heat Treatment, Bending, Annealed, Machining Etc. |

| End Connections | Plain, Bevel, Screwed, Threaded |

| Type | Seamless / ERW / Welded / Fabricated / CDW |

Test Certificate |

Manufacturer Test Certificate, IBR Test Certificate, Laboratory Test Certificate from Govt. Approved Lab Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports, India Boiler Regulations (IBR) Test Certificate |

| ASTM A213/ ASME SA213 T91 Alloy Steel Seamless Tube Form | Round Pipes/Tubes, Square Pipes/Tubes, Rectangular Pipe/Tubes, Coiled Tubes, “U” Shape, Pan Cake Coils, Hydraulic Tubes, special shape tube etc. |

| ASTM A213/ ASME SA213 T91 Alloy Steel Seamless Tube End | Plain End, Beveled End, Threaded |

| Specialize | ASTM A213 T91 Heat Exchanger & Condenser Tubes |

| Outside Coating | Black Painting, Anti-Corrosion Oil, Galvanised Finish, Finish as per customer Requirements |

T91 Seamless (SMLS) tube is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable.

The greatest advantage of T91 seamless steel tubes is their increased ability to withstand pressure. The weakest point in a T91 welded steel tube is the welded seam. But because a seamless steel pipe has not been welded, it doesn’t have that seam, making it equally strong around the entire circumference of the pipe.

- Size range: 1/2” OD up to 5” OD, customs diameters also available

- Wall Thickness up through 4” thick& heavier upon request

- Alloy Steel Tube Specifications & Grades:

- SA-335 P5, P9, P11, P22, P91

- SA-213 T5, T9, T11, T22, T91

- A519 4130, 4140/42

- Rolled & Welded A-691

We are the Approved Suppliers and wanders’ of HPCL , IFFCO, NRL Limited , Torrent Power since one Decade

10,000 sqft, Navi Mumbai, Kalamboli

Ready Stock Available |

|

|---|---|

| Alloy Steel T91 Seamless Pipes | 100 ton |

| Steel Grade | Pipe | Tube | Fittings | Plate | Forgings |

|---|---|---|---|---|---|

| 1/2Mo | A335 P1 | A213 T1 | A234 WP1 | A182 F1 | |

| 5Cr-1/2Mo | A335 P5 | A213 T5 | A234 WP5 | A387 GRADE 5 | A182 F5 |

| 9Cr-1Mo | A335 P9 | A213 T9 | A234 WP9 | A387 GRADE 9 | A182 F9 |

| 1 1/4 Cr-1/2Mo | A335 P11 | A213 T11 | A234 WP11 | A387 GRADE 11 | A182 F11 |

| 2 1/4Cr-1Mo | A335 P22 | A213 T22 | A234 WP22 | A387 GRADE 22 | A182 F22 |

| 9Cr-1Mo-V-Nb | A335 P91 | A213 T91 | A234 WP91 | A387 GRADE 91 | A182 F91 |

SA213 T91 Tube Price, A213 T91 Tubing Price, ASTM A213 grade T91 Price, T91 Boiler Tube Price, ASTM A213 T91 Price in India

- ASTM A213 T91 Steel Pipe

US $800-1500 / Metric Ton (FOB Price) - T91 seamless alloy steel pipe

US $1000-2500 / Ton (FOB Price) - ASTM A213 T91 Alloy Steel Bolier Tubes

US $680-900 / Ton (FOB Price) - astm a213 t91 steel tube

US $700-3500 / Ton (FOB Price) - ASTM A213 T91 boiler tube

US $600-1200 / Metric Ton (FOB Price) - astm a213 t91 steel tube price

US $500-1500 / Ton (FOB Price) - astm a213 t91 seamless steel boiler tubes

US $360-420 / Ton(FOB Price) - ASTM A213 T91 seamless alloy steel boiler tube

US $600-800 / Ton (FOB Price) - astm a213 t91 steel tube price seamless low ally steel tubes

US $1580-3250 / Ton (FOB Price) - low price ASTM A213 T91 seamless tube

US $1900.0-2299.0 / Tons (FOB Price)

Types of Types of ASTM A213 T91 / ASME SA213 T91 Alloy Steel Seamless Tube

ASTM A213 T91 Alloy Steel seamless tube

ASTM A213 T91 Alloy Steel seamless tube

The material T91 & P91 seamless tube is especially suited for steam boiler, boiler parts, boiler drum, pressure vessel for the apparatus engineering and similar purposes. It can be used in permanent operation with wall temperatures up to about 590 °C ‘1094 °F+.

ASTM SA335 Chrome Moly Tube Grade T91

Steel Pipes Online is a premier worldwide supplier for all your Chrome Moly Alloy A213 / SA213 Seamless Piping needs. These ASTM S/A 335 Chrome Moly Grade T91 Tube may be furnished bare or coated and with capped ends.

Steel Pipes Online is a premier worldwide supplier for all your Chrome Moly Alloy A213 / SA213 Seamless Piping needs. These ASTM S/A 335 Chrome Moly Grade T91 Tube may be furnished bare or coated and with capped ends.

ASTM A213 T91 High Pressure Steel Tubes

We are stockholder & suppliers of High pressure T91 Seamless tubes and pipes, mostly used in Power Plants. The products are supplied with 3.1 test certificates, according to EN 10204. Certification according to 3.2 can be agreed at the time of order.

We are stockholder & suppliers of High pressure T91 Seamless tubes and pipes, mostly used in Power Plants. The products are supplied with 3.1 test certificates, according to EN 10204. Certification according to 3.2 can be agreed at the time of order.

ASTM A213 T91 Boiler Tube

Supplying T91 Boiler Tube & Seamless hot finished tubes and pipes for utility boilers, industrial boilers and heat recovery steam generators. The T91 tubes and pipes are supplied in random lengths or in fixed lengths to be analysed and agreed at time of order, in the range between 4,000 mm and 26,000 mm depending on the size.

Supplying T91 Boiler Tube & Seamless hot finished tubes and pipes for utility boilers, industrial boilers and heat recovery steam generators. The T91 tubes and pipes are supplied in random lengths or in fixed lengths to be analysed and agreed at time of order, in the range between 4,000 mm and 26,000 mm depending on the size.ASTM A213 T91 Alloy Steel Seamless Tubes, ASTM A213 T91 Alloy Steel Seamless Pipes

| Pipe/ Tube Type | NB Sizes | Sch 5 | Sch 10 | Sch 40 | Sch 80 | Sch 160 |

|---|---|---|---|---|---|---|

| ASTM A213 T91 Alloy Steel Seamless Tubes | 1/2 |

|||||

| ASTM A213 T91 Alloy Steel Seamless Tubes | 3/4 |

|||||

| ASTM A213 T91 Alloy Steel Seamless Tubes | 1 |

|||||

| ASTM A213 T91 Alloy Steel Seamless Tubes | 1.25 |

|||||

| ASTM A213 T91 Alloy Steel Seamless Tubes | 1.5 |

|||||

| ASTM A213 T91 Alloy Steel Seamless Tubes | 2 |

|||||

| ASTM A213 T91 Alloy Steel Seamless Tubes | 2.5 |

|||||

| ASTM A213 T91 Alloy Steel Seamless Tubes | 3 |

|||||

| ASTM A213 T91 Alloy Steel Seamless Tubes | 3.5 |

|||||

| ASTM A213 T91 Alloy Steel Seamless Tubes | 4 |

|||||

| ASTM A213 T91 Alloy Steel Seamless Tubes | 5 |

|||||

| ASTM A213 T91 Alloy Steel Seamless Tubes | 6 |

|||||

| ASTM A213 T91 Alloy Steel Seamless Tubes | 8 |

|||||

| ASTM A213 T91 Alloy Steel Seamless Tubes | 10 |

|||||

| ASTM A213 T91 Alloy Steel Seamless Tubes | 12 |

|||||

| ASTM A213 T91 Alloy Steel Seamless Tubes | 14 |

|||||

| ASTM A213 T91 Alloy Steel Seamless Tubes | 16 |

|||||

| ASTM A213 T91 Alloy Steel Seamless Tubes | 18 |

|||||

| ASTM A213 T91 Alloy Steel Seamless Tubes | 20 |

|||||

| ASTM A213 T91 Alloy Steel Seamless Tubes | 22 |

|||||

| ASTM A213 T91 Alloy Steel Seamless Tubes | 24 |

ASTM A213 T91 Alloy Steel Seamless Tubes, ASTM A213 T91 Alloy Steel Seamless Pipes Chemical Composition %

| C, % | Mn, % | P, % | S, % | Si, % | Cr, % | Mo, % | V, % | N, % | Ni, % | Al, % | Nb, % |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.08-0.12 | 0.3-0.6 | 0.02 max | 0.01 max | 0.2-0.5 | 8.0-9.5 | 0.85-1.05 | 0.18-0.25 | 0.03-0.07 | 0.4 max | 0.04 max | 0.06-0.10 |

ASTM A213 T91 Alloy Steel Seamless Tubes, ASTM A213 T91 Alloy Steel Seamless Pipes Mechanical Properties

| Tensile Strength , MPa | Yield Strength, MPa | Elongation, % | Hardness, HB |

|---|---|---|---|

| 585 min | 415 min | 20 min | 250 max |

ASTM A213 T91 Alloy Steel Seamless Tubes, ASTM A213 T91 Alloy Steel Seamless Pipes Tolerance

Outside Diameter |

OD Tolerance |

WT Tolerance |

Ovality Tolerance |

Cut Length Tolerance |

|---|---|---|---|---|

OD≤ 12, 7 mm |

± 0, 13 mm |

± 15 % |

– |

+ 3, 18 mm, – 0 mm |

12, 7 mm < OD ≤ 38, 1 mm |

± 0, 13 mm |

± 10 % |

max, 1, 65 mm |

+ 3, 18 mm, – 0 mm |

38, 1 mm < OD ≤ 88, 9 mm |

± 0, 25 mm |

± 10 % |

max, 2, 41 mm |

+ 4, 76 mm, – 0 mm |

Alloy Steel Boiler and Heat Exchanger Tubes

| ASTM | ASME | JIS G 3462 | BS | DIN | ISO | ABS | NK | LRS | DNV |

|---|---|---|---|---|---|---|---|---|---|

| A209 T1 | SA209 T1 | STBA 12 | 3606 243 | 17175 15Mo3 |

2604 II TS26 | ABS K | KSTB 12 | Sec 4-E-TS380 |

|

| A250 T1 | SA250 T1 | 3606 245 | 17177 15Mo3 |

2604 III TS26 | |||||

| A209 T1a | SA209 T1a | STBA 13 | ABS L | ||||||

| A250 T1a | SA250 T1a | ||||||||

| A213 T2 | SA213 T2 | STBA 20 | 17175 14MoV83 |

2604 II TS33 | Sec 4-E-TS440 |

||||

| A250 T2 | SA250 T2 | ||||||||

| A213 T12 | SA213 T12 | STBA 22 | 3606 620 | 17175 13CrMo44 |

2604 II TS32 | ABS O | KSTB 22 | Sec 6 1Cr 1/2Mo-440 |

Sec 4-E-TS410-3 |

| A250 T12 | SA250 T12 | 2604 III TS32 | |||||||

| A213 T11 | SA199 T11 | STBA 23 | 3606 621 | ABS N | KSTB 23 | Sec 4-E-TS410-4 |

|||

| SA213 T11 | |||||||||

| A213 T22 | SA199 T22 | STBA 24 | 3606 622 | 17175 10CrMo910 |

2604 II TS34 | ABS P | KSTB 24 | Sec 6 2-1/2Cr 1Mo-410 |

Sec 4-E-TS450-2 |

| SA213 T22 | |||||||||

| A213 T5 | SA199 T5 | STBA 25 | 3606 625 | 2604 II S37 | Sec 4-E-TS430 |

||||

| SA213 T5 | |||||||||

| A213 T9 | SA199 T9 | STBA 26 | 3059-P2 622-490 | 2604 II S38 | Sec 4-E-TS500 |

||||

| SA213 T9 | |||||||||

| A209 T1b | SA209 T1b | 3059-P2 243 | 17175 17Mn4 |

2604 II S39 | ABS M | Sec 6 2-1/2Cr 1Mo-490 |

Sec 4-E-TS450-1 |

||

| 3059-P2 620-460 | (=A209- T1b) |

||||||||

| A250 T1b | SA250 T1b | 3059-P2 629-470 | 17175 14MoV63 |

2604 II S40 | Sec 4-E-TS460-2 |

||||

| A250 T11 | SA250 T11 | 3059-P2 629-590 | 17175 X20CrMoV12 1 |

Sec 4-E-TS590 |

|||||

| A250 T22 | SA250 T22 | 3059-P2 762 | Sec 4-E-TS610 |

||||||

| A213 T5b | SA213 T5b | 3059-P2 304S51 | Sec 4-E-TS690 |

||||||

| A213 T5c | SA213 T5c | 3059-P2 306S51 | |||||||

| A213 T17 | SA213 T17 | 3059-P2 316S52 | |||||||

| A213 T21 | SA213 T21 | 3059-P2 316S51 | |||||||

| A213 T23 | SA213 T23 | 3059-P2 321S51 | |||||||

| A213 T91 | SA213 T91 | 3059-P2 347S51 | |||||||

| A213 T92 | SA213 T92 | 3059-P2 215S15 |

Check Our Heavy Sale Products of ASTM A213 T91 Tube / ASME SA213 T91 Alloy Steel Seamless Tubes at most attractive price offer

| Other types of ASTM A213 T91 / ASME SA213 T91 Alloy Steel Seamless Tube | ||

|---|---|---|

|

|

|

Alloy Steel Pipes, Tubes, Alloy Steel P9 Seamless Pipes Specifications

SAE/AMS Specifications| SAE-J356 | Welded Flash Controlled Low Carbon Steel Tubing Normalized for Bending. Double Flaring and Beading. Covers normalized electric resistance welded tube ID flash-controlled .005" to .010" manipulative quality. |

|---|---|

| SAE-J524 | Seamless Low Carbon Steel Tubing Annealed for Bending and Flaring. Covers cold drawn seamless JIC hydraulic line tubing. |

| SAE-J525 | Welded and Drawn Low Carbon Steel Tubing Annealed for Bending and Flaring. Covers welded and drawn JIC hydraulic line tubing. |

| SAE-J526 | Welded Low Carbon Steel Tubing. Covers annealed welded tube with ID flash-in for general automotive applications. |

| SAE-J527 | Brazed Double Wall Carbon Steel Tubing. Covers copper brazed double wall low carbon steel tube intended for general automotive applications and other similar uses. Suitable for bending, forming and double flaring. |

| SAE-J529 | Fuel Injection Tubing. Covers low carbon steel tube specially manufactured for high pressure fuel injection lines for diesel engines. |

| AMS-5050 | Seamless Annealed Low Carbon Steel Tube. Covers cold drawn seamless JIC hydraulic line steel tubing for aircraft applications. |

| AMS-5062 | Seamless Low Carbon Steel Tube. Covers cold finished or hot finished seamless low carbon mechanical steel tube. |

| AMS-6360 | Seamless SAE 4130 Alloy Steel Tubing. Covers aircraft quality 4130 tube in condition N temper. Similar to MIL-T-6736 specification. |

| AMS-6365 | Seamless SAE 4135 Alloy Steel Tubing. Covers aircraft quality 4135 tube in condition N temper. Similar to MIL-T-6735 specification. |

| AMS-6371 | Seamless SAE 4130 Alloy Steel Mechanical Tubing. Covers electric furnace grade magnaflux quality 4130 aircraft tube, either hot finished or cold finished, hardenable. |

| AMS-6372 | Seamless SAE 4135 Alloy Steel Mechanical Tubing. Covers electric furnace grade magnaflux quality 4135 aircraft tube, either hot finished or cold finished, hardenable. |

| AMS-6381 | Seamless SAE 4140 Alloy Steel Mechanical Tubing. Covers electric furnace grade magnaflux quality 4140 aircraft tube, either hot finished or cold finished, hardenable. |

| AMS-6415 | Seamless SAF 4340 Alloy Steel Mechanical Tubing. Covers electric furnace grade magnaflux quality 4340 aircraft tube, either hot finished or cold finished, hardenable. |

ASTM A213 T91 /ASME SA213 T91 Alloy Steel Pipe Useful Information

| Tubular Products |

|---|

| ASTM A519 Standard Specification for Seamless Carbon and Alloy Steel Mechanical Tubing 4130 DIN 17175 Seamless Tubes of Heat-resistant Steels GOST 8732-78 Seamless Hot-worked Steel Pipes GOST 8734-75 Seamless cold-formed steel pipes GOST 550-75 Seamless steel tubes for petroleum processing and the petrochemical industry TU 14-3R-55-2001 Seamless steel pipes for steam boilers and pipelines TU 14-3-460-2003 Seamless steel tubes for boilers and pipelines GOST 9567-75 Precision steel pipes |

| ASTM A213 T91 / ASME SA213 T91 Alloy Steel Seamless Tube Available Surface Finish |

|---|

Surface Finishes: Bare, Oiled, Mill Varnish, Galv, FBE, FBE Dual, 3LPE, 3LPP, Coal Tar, Concrete Coating and Tape Wrap.

End Finishes: Beveled, Square Cut, Threaded & Coupled.

| Our Specialization in ASTM A213 T91 / ASME SA213 T91 Alloy Steel Seamless Tube |

|---|

Looking for ASTM A213 T91 / ASME SA213 T91 Alloy Steel Seamless Tube specialized & reliable suppliers in India?

Steel Pipes Online is India’s leading suppliers & exporter of Alloy Steel Pipes & Tubes,ASTM A213/ASME SA213 T2, T11, T12, T22, T91, T92 grade alloy steel pipes, Chrome Moly Alloy A213 / SA213 heater tubes and alloy steel tubes. Alloy steel tubes are generally available in stock with OD sizes in all standard sizes and thicknesses. ANSI B 36.10, Alloy Steel GR. P22 Seamless Round, Square, Rectangular, Hydraulic Pipes Suppliers in India. We have specialization in ASTM A213 Gr T91 Seamless Tubes and Pipes for Power Plants | ASTM A213 Gr T91 Seamless hot finished tubes and pipes for utility boilers, industrial boilers and heat recovery steam generators | ASTM A213 Gr T91 Cold drawn seamless tubes for heat exchangers and boilers

We have supplied ASTM A213/ ASME SA213 T91 Alloy Steel Seamless Tube to 280+ companies from Oil & Gas Industry, Petrochemical, Offshore & Onshore Projects, Rigs, Chemical & Fertilizer companies in more than 80 countries.

| ASTM A213 T91 / ASME SA213 T91 Alloy Steel Seamless Tube Outside Diameter & Tolerance |

|---|

Hot rolled ASTM A213/ ASME SA213 T91 Alloy Steel Seamless Tube |

Outside Diameter, mm |

Tolerance, mm |

OD≤101.6 |

+0.4/-0.8 |

|

101.6<OD≤190.5 |

+0.4/-1.2 |

|

190.5<OD≤228.6 |

+0.4/-1.6 |

|

Cold Drawn ASTM A213/ ASME SA213 T91 Alloy Steel Seamless Tube |

Outside Diameter, mm |

Tolerance, mm |

OD<25.4 |

±0.10 |

|

25.4≤OD≤38.1 |

±0.15 |

|

38.1<OD<50.8 |

±0.20 |

|

50.8≤OD<63.5 |

±0.25 |

|

63.5≤OD<76.2 |

±0.30 |

|

76.2≤OD≤101.6 |

±0.38 |

|

101.6<OD≤190.5 |

+0.38/-0.64 |

|

190.5<OD≤228.6 |

+0.38/-1.14 |

| ASTM A213 T91 / ASME SA213 T91 Alloy Steel Seamless Tube Wall thickness & Tolerance |

|---|

Hot rolled ASTM A213/ ASME SA213 T91 Alloy Steel Seamless Tube

|

Outside Diameter, mm |

Tolerance, % |

OD≤101.6, WT≤2.4 |

+40/-0 |

|

OD≤101.6, 2.4<WT≤3.8 |

+35/-0 |

|

OD≤101.6, 3.8<WT≤4.6 |

+33/-0 |

|

OD≤101.6, WT>4.6 |

+28/-0 |

|

OD>101.6, 2.4<WT≤3.8 |

+35/-0 |

|

OD>101.6, 3.8<WT≤4.6 |

+33/-0 |

|

OD>101.6, WT>4.6 |

+28/-0 |

|

Cold Drawn ASTM A213/ ASME SA213 T91 Alloy Steel Seamless Tube

|

Outside Diameter, mm |

Tolerance, % |

OD≤38.1 |

+20/-0 |

|

OD>38.1 |

+22/-0 |

Length: 5800mm; 6000mm; 6096mm; 11800mm; 12000mm; and so on.

Max length: 16000mm

Keyword: High Pressure Steel Pipe, Boiler Tubes manufacturer, Boiler Steel Pipe, ASME SA213, T91, ASTM A213

Length: 5800mm; 6000mm; 6096mm; 11800mm; 12000mm; and so on.

Max length: 16000mm

Applications Of ASTM A213 T91 / ASME SA213 T91 Alloy Steel Seamless Tube

- Refineries

- Power Plants

- Boilers

- Ship Building

- Heat Exchangers

- Condensers

- Paper & Pulp

- Marine Applications

- Nuclear Power

- Fossil Fuel Power Plants

ASTM A213 T91 / ASME SA213 T91 Alloy Steel Seamless Tube Packaging & Shipping

ASTM A213 T91 in Seamless & Welded both are loose or in bundles tightened with Iron Strips. Special packings: Metal or Wooden Cases, Pallets etc. Plastic closes both ends, Hexagonal bundles maximum 2.000 kg with several steel strips, Two tags on each bundle, Wrapped in waterproof paper, PVC sleeve, and IN in sackcloth with several steel strips, Plastic caps.

Both ends of each crate will indicate the order no., heat no., dimensions, weight and bundles or as requested. We can also offer customized packaging for ASTM A213 T91 as per customer's requirement.

Marking Requirements

Marking Requirements

Rolled, die stamped, or paint stenciled (manufacturer’s option).

- Manufacturer’s name, brand, or trademark

- ASTM A213 T91

- ANSI schedule number or weight class or wall thickness

- Additional “S” if tested supplementary requirements

- Hydrostatic test pressure and/or NDE, or NH if neither is specified

- Size, length, weight per foot (NPS 4 and larger)

Overseas Packaging

Export packaging is geared towards the protection, handling and transport of ASTM A213 T91 by air or sea freight and, as such, shares many characteristics with export and transport packaging. Utmost care must also be taken to make overseas packaging suitable for long periods of storage. It is important for overseas packaging to be designed with ease of handling in mind, so as to ensure ASTM A213 T91 is treated with the utmost care at all times.

Brands we Stock & Supply of ASTM A213 T91 Tubes

Authorised Dealer & distributor of |

||||

|---|---|---|---|---|

United Seamless Limited -usl ASTM A213 T91 Tubes |

Bao Steel- Bao ASTM A213 T91 Tubes |

Yangzhou Lontrin Steel Tube -lontrinASTM A213 T91 Tubes |

Sumitomo Metals Smtm ASTM A213 T91 Tubes |

Tenaris -tnrs ASTM A213 T91 Tubes |

Valourec & Mannesman -v&m ASTM A213 T91 Tubes |

Wuxi ASTM A213 T91 Tubes |

Maharastra Seamless Limited -msl ASTM A213 T91 Tubes |

Indian Seamless Metal Tubes Limited _ismt ASTM A213 T91 Tubes |

Jindal Saw Ltd -jsl ASTM A213 T91 Tubes |

We are approved vendor & Suppliers ofASTM A213 T91 Tubes in GASCO, KNPC, SAUDI ARAMCO, SABIC, ORPIC, NIORDC, PIDMCO etc.

Vendor & Suppliers of |

|||||

|---|---|---|---|---|---|

GASCO |

KNPC |

SAUDI ARAMCO |

SABIC |

ORPIC |

PIDMCO |

Mumbai |

Thane |

Navi Mumbai |

Pune |

Pimpri-Chinchwad |

Vadodara |

Kolkata |

Gurgaon |

Ahmedabad |

New Delhi |

Bengaluru |

Chennai |

Surat |

Bhopal |

Ulsan |

Faridabad |

Houston |

Dubai |

Seoul |

Hyderabad |

Singapore |

Abu Dhabi |

Tehran |

Calgary |

Noida |

Riyadh |

London |

Coimbatore |

Jakarta |

Istanbul |

Bangkok |

Kuwait City |

Sharjah |

Muscat |

Edmonton |

Edmonton |

Busan |

Mexico City |

Doha |

Jeddah |

Aberdeen |

Cairo |

Geoje-si |

Perth |

Santiago |

Chandigarh |

Indore |

Kuala Lumpur |

Rio de Janeiro |

Dammam |

Melbourne |

Madrid |

La Victoria |

Bogota |

Lahore |

Los Angeles |

Algiers |

Chiyoda |

Ankara |

Ho Chi Minh City |

Toronto |

Hong Kong |

Rajkot |

Brisbane |

Petaling Jaya |

Ernakulam |

Secunderabad |

Gimhae-si |

Al Jubail |

Port-of-Spain |

Thiruvananthapuram |

Milan |

Atyrau |

Lagos |

Hanoi |

Howrah |

Sydney |

Ahvaz |

Karachi |

New York |

Caracas |

Vung Tau |

Al Khobar |

Manama |

Montreal |

Granada |

Courbevoie |

Visakhapatnam |

Ludhiana |

Moscow |

Dallas |

Haryana |

Colombo |

India |

Saudi Arabia |

Bangladesh |

United States |

UAE |

Canada |

Angola |

Argentina |

Austria |

Azerbaijan |

Pakistan |

Peru |

Chile |

Spain |

France |

United Kingdom |

Indonesia |

Israel |

Iran |

Kuwait |

Mexico |

Malaysia |

Nigeria |

Serbia |

Singapore |

Taiwan |

Chile |

Venezuela |

Ecuador |

Netherlands |

Brazil |

Colombia |

Ghana |

Iran |

Denmark |

Poland |

Australia |

Afghanistan |

Bahrain |

Costa Rica |

Egypt |

Iraq |

Jordan |

South Korea |

Kazakhstan |

Sri Lanka |

Lithuania |

Norway |

Oman |

Philippines |

Poland |

Qatar |

Russia |

Vietnam |

South Africa |

Nigeria |

Mexico |

Turkey |

Hungary |

Algeria |

Belarus |

Belgium |

Bhutan |

Bolivia |

Bulgaria |

Croatia |

Czech Republic |

Estonia |

Finland |

Greece |

Italy |

Japan |

Libya |

Romania |

Thailand |

Trinidad |

Tobago |

Tunisia |

Ukraine |

Yemen |

Hong Kong |

Gabon |

China |

Portugal |

Switzerland |

New Zealand |

Sweden |

Slovakia |

Kenya |

Lebanon |

Morocco |

Mongolia |