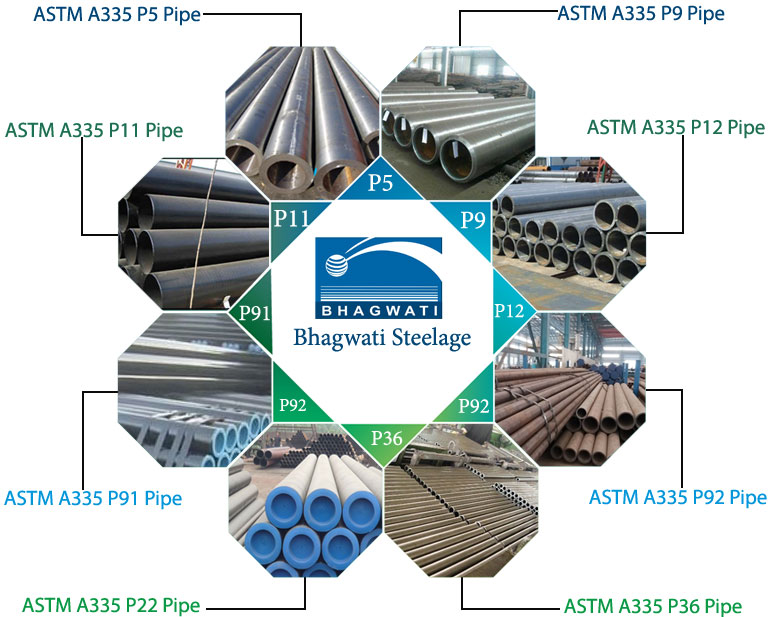

ASTM A335 Alloy Steel Seamless Pipes Manufacturers In India, Global Suppliers Of High Quality ASTM A335 Alloy Steel Pipes, ASTM A335 P5 Pipe, ASTM A335 P11 Pipe, ASTM A335 P12 Pipe, ASTM A335 P22 Pipe, ASTM A335 P22 Pipe, ASTM A335 P92 Pipe, ASTM A335 P91 Seamless Pipes, ASTM A 335 Gr P91, ASTM A335 P92 Seamless Pipes, ASTM A 335 Gr P92, A335 P5 Pipe Suppliers, A335 P11 Pipe Suppliers, A335 P12 Pipe Suppliers, A213 T22 Tube Suppliers In India

“chrome Moly” ASTM A335/ASME SA335 Grades P5, P9, P11, P22, P91 Steel Pipes Exporters In India, ASTM A335 P5 Alloy Steel Seamless Pipes Suppliers, ASTM A335 P5 Seamless Pipes, ASTM A 335 Gr P5, ASTM A335 P11 Alloy Steel Seamless Pipes Suppliers, ASTM A335 P11 Seamless Pipes, ASTM A 335 Gr P11,a335 P22 Pipe Suppliers, ASTM A335 P92, A335 P91 Pipe Manufacturers In India, A335 P22 Pipe Suppliers In India, A335 P5 Pipe Suppliers In India

ASTM A335 Seamless Pipes, ASTM A335 P5, P9, P11, P22, P91 Seamless Steel Tubes Suppliers, ASTM A335 P12 Alloy Steel Seamless Pipes Suppliers, ASTM A335 P12 Seamless Pipes, ASTM A 335 Gr P12, ASTM A335 P22 Alloy Steel Seamless Pipes Suppliers in India, ASTM A335 P22 Seamless Pipes Manufacturers In India, ASTM A 335 Gr P22 Manufacturers In India, a335 P91 Pipe Suppliers, A335 P12 Pipe Suppliers In India, A335 P11 Pipe Suppliers In India

- ASTM A333 P1 Pipe

- ASTM A333 P2 Pipe

- ASTM A333 P5 Pipe

- ASTM A333 P9 Pipe

- ASTM A333 P11 Pipe

- ASTM A333 P12 Pipe

- ASTM A333 P15 Pipe

- ASTM A333 P21 Pipe

- ASTM A333 P22 Pipe

- ASTM A333 P23 Pipe

- ASTM A333 P24 Pipe

- ASTM A333 P36 Pipe

- ASTM A333 P91 Pipe

- ASTM A333 P92 Pipe

- ASTM A333 P122 Pipe

- ASTM A333 P911 Pipe

- ASME SA333 P5 Pipe

- ASME SA333 P9 Pipe

- ASME SA333 P91 Pipe

- ASME SA333 P92 Pipe

Alloy Steel Pipes at most attractive price offer

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ASTM A335 P5, ASTM A335 P9, ASTM A335 P11, ASTM A335 P22, ASTM A335 P91 Alloy Steel Pipes Manufacturers In India

ASTM A335/ASME SA 335 P5, P9, P11, P22, P91 Seamless Pipes, Tubes Supplier, Exporters in India

Government and Public Sector Companies Approved Suppliers of ASTM a335 , p5 , p9 , p11 , p22 , p91 , Alloy Steel Pipes Tubing

ASTM A335/ASME SA335 P5, P9, P11, P22, P91 Seamless Alloy Steel Pipes Exporter and Supplier, A335 P11 pipe suppliers, A335 P12 pipe suppliers, A335 P22 pipe suppliers, A335 P91 pipe suppliers, astm a335 p92 ,a335 p91 pipe suppliers in india ,a335 p22 pipe suppliers in india,a335 p12 pipe suppliers in india,a335 p11 pipe suppliers in india,a335 p5 pipe suppliers in india,a213 t22 tube suppliers in india .

10,000 sqft, Navi Mumbai, Kalamboli

| Ready Stock Available | |

|---|---|

| ASTM A335 P5 Pipes | 100 ton |

| ASTM A335 P9 Pipes | 100 ton |

| ASTM A335 P11 Pipes | 100 ton |

| ASTM A335 P22 Pipes | 200 ton |

| ASTM A335 P91 Pipes | 100 ton |

A335 P11 Pipe Suppliers, A335 P12 Pipe Suppliers, A335 P22 Pipe Suppliers, A335 P91 Pipe Suppliers, Astm A335 P92, ASTM A335/ASME SA 335 P5, P9, P11, P22, P91 Seamless Pipes, Tubes Specifications, Stock And Supply Range

- Size Range: 1/2” NB to 36” NB

- Thickness Range: SCH 40, SCH 80, SCH 160, SCH XS, SCH XXS, All Schedules

- Alloy Steel Pipes Specifications: ASTM A/ASME SA 335 P1, P2, P5, P9, P11, P12, P22, P23, P91, and P92

End Connections for Line Pipes: Plain, Bevel, Screwed, Threaded

Type: Seamless / ERW / Welded / Fabricated / CDW

Form: Round Pipes/Tubes, Square Pipes/Tubes, Rectangular Pipe/Tubes, Coiled Tubes, “U” Shape, Pan Cake Coils, Hydraulic Tubes

Length: Single Random, Double Random & Required Length, Custom Size – 12 Meter lengths

End: Plain End, Beveled End, Treaded

End Protection: Plastic Caps

Outside Coating: Black Painting, Anti-Corrosion Oil, Galvanised Finish, Finish as per customer Requirements

Inspection, Test Reports: Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports, India Boiler Regulations (IBR) Test Certificate

Packing: Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests

Specials: Sizes and Specifications other than above can be Supplier on request

ASTM A / ASME SA 335, ASTM A335 P5, ASTM A335 P9, ASTM A335 P11, ASTM A335 P22, ASTM A335 P91 Alloy Steel Pipes– Standard Specification For Seamless Ferritic Alloy-Steel Pipe For High-Temperature Service

This specification covers seamless ferritic alloy-steel pipe for high-temperature service. The pipe shall be suitable for bending, flanging (vanstoning), and similar forming operations, and for fusion welding. Grade P2 and P12 steel pipes shall be made by coarse-grain melting practice. The steel material shall conform to chemical composition, tensile property, and hardness requirements. Each length of pipe shall be subjected to the hydrostatic test. Also, each pipe shall be examined by a non-destructive examination method in accordance to the required practices. The range of pipe sizes that may be examined by each method shall be subjected to the limitations in the scope of the respective practices. The different mechanical test requirements for pipes, namely, transverse or longitudinal tension test, flattening test, and hardness or bend test are presented.

Trade Name |

Grade |

UNS # |

Pipe |

Forged / Bored Pipe * |

1 1/4 Chrome |

P11 |

K11597 |

A335 / SA335 |

A369 / SA369 |

2 1/4 Chrome |

P22 |

K21590 |

A335 / SA335 |

A369 / SA369 |

5 Chrome |

P5 |

K41545 |

A335 / SA335 |

A369 / SA369 |

9 Chrome |

P9 |

S50400 |

A335 / SA335 |

A369 / SA369 |

P91 |

P91 |

K91560 |

A335 / SA335 |

A369 / SA369 |

P92 |

P92 |

K92460 |

A335 / SA335 |

A369 / SA369 |

astm a335 p11 price, astm a335 p91 pipe price, astm a335 gr p22 price, astm a335 gr p9 price

- ASTM A335 P5, P9,P11,P22,P91 seamless alloy steel pipe

US $345-430 / Ton(FOB Price) - ASTM A335 P5 P22 P91 Alloy Steel Tube

US $850-2530 / Piece(FOB Price) - ASTM A335 P9 seamless alloy pipe

US $788.90-2999.89 / Ton(FOB Price) - P92 alloy steel pipe

US $600-1800 / Metric Ton(FOB Price) - ASTM A335 P11 LOW ALLOY STEEL PIPE

US $300-500 / Ton (FOB Price) - High quality ASTM A335 P91 Seamless alloy steel pipe

US $599-1099 / Ton(FOB Price) - ASTM A335/ Seamless alloy steel pipe P91 P22 P11 P9 material

US $1000-1500 / Ton(FOB Price) - Black round astm a335 gr p91 chrome plated steel pipe

US $800-1100 / Ton (FOB Price) - astm a335 p91 seamless pipe

US $479-599 / Ton (FOB Price) - ASTM A335 p91 alloy pipes

US $600-2500 / Ton (FOB Price)

ASTM A335 P5, ASTM A335 P9, ASTM A335 P11, ASTM A335 P22, ASTM A335 P91 Alloy Steel Pipes Size & Stock Range

| Pipe/ Tube Type | NB Sizes | Sch 5 | Sch 10 | Sch 40 | Sch 80 | Sch 160 |

|---|---|---|---|---|---|---|

| ASTM A335 P5, P9, P11, P22, P91 Alloy Steel Pipes | 1/2 |

|||||

| ASTM A335 P5, P9, P11, P22, P91 Alloy Steel Pipes | 3/4 |

|||||

| ASTM A335 P5, P9, P11, P22, P91 Alloy Steel Pipes | 1 |

|||||

| ASTM A335 P5, P9, P11, P22, P91 Alloy Steel Pipes | 1.25 |

|||||

| ASTM A335 P5, P9, P11, P22, P91 Alloy Steel Pipes | 1.5 |

|||||

| ASTM A335 P5, P9, P11, P22, P91 Alloy Steel Pipes | 2 |

|||||

| ASTM A335 P5, P9, P11, P22, P91 Alloy Steel Pipes | 2.5 |

|||||

| ASTM A335 P5, P9, P11, P22, P91 Alloy Steel Pipes | 3 |

|||||

| ASTM A335 P5, P9, P11, P22, P91 Alloy Steel Pipes | 3.5 |

|||||

| ASTM A335 P5, P9, P11, P22, P91 Alloy Steel Pipes | 4 |

|||||

| ASTM A335 P5, P9, P11, P22, P91 Alloy Steel Pipes | 5 |

|||||

| ASTM A335 P5, P9, P11, P22, P91 Alloy Steel Pipes | 6 |

|||||

| ASTM A335 P5, P9, P11, P22, P91 Alloy Steel Pipes | 8 |

|||||

| ASTM A335 P5, P9, P11, P22, P91 Alloy Steel Pipes | 10 |

|||||

| ASTM A335 P5, P9, P11, P22, P91 Alloy Steel Pipes | 12 |

|||||

| ASTM A335 P5, P9, P11, P22, P91 Alloy Steel Pipes | 14 |

|||||

| ASTM A335 P5, P9, P11, P22, P91 Alloy Steel Pipes | 16 |

|||||

| ASTM A335 P5, P9, P11, P22, P91 Alloy Steel Pipes | 18 |

|||||

| ASTM A335 P5, P9, P11, P22, P91 Alloy Steel Pipes | 20 |

|||||

| ASTM A335 P5, P9, P11, P22, P91 Alloy Steel Pipes | 22 |

|||||

| ASTM A335 P5, P9, P11, P22, P91 Alloy Steel Pipes | 24 |

ASTM A335 P5, ASTM A335 P9, ASTM A335 P11, ASTM A335 P22, ASTM A335 P91 Alloy Steel Pipes Chemical Composition %

Grade |

C |

Mn |

P |

S |

Si |

Cr |

Mo |

|---|---|---|---|---|---|---|---|

P5 |

0.15max |

0.30-0.60 |

0.025 |

0.025 |

0.50 max |

4.00-6.00 |

0.45-0.65 |

P9 |

0.15 max |

0.30-0.60 |

0.025 |

0.025 |

0.25-1.00 |

8.00-10.00 |

0.90-1.10 |

P11 |

0.05-0.15 |

0.30-0.60 |

0.025 |

0.025 |

0.50-1.00 |

1.00-1.50 |

0.44-0.65 |

P22 |

0.05-0.15 |

0.30-0.60 |

0.025 |

0.025 |

0.50 max |

1.90-2.60 |

0.87-1.13 |

P91 |

0.08-0.12 |

0.30-0.60 |

0.02 |

0.01 |

0.20-0.50 |

8.00-9.50 |

0.85-1.05 |

V 0.18-0.25 |

N 0.03-0.07 |

Ni 0.40 max |

Al 0.02 max |

Cb 0.06-0.10 |

Ti 0.01 max |

Zr 0.01 max |

ASTM A335 P5, ASTM A335 P9, ASTM A335 P11, ASTM A335 P22, ASTM A335 P91 Alloy Steel Pipes Mechanical Properties

Mechanical Properties |

|||||

Grade |

Tensile strength(MPa) |

Yield strength(MPa) |

Elongation(%) |

Impact energy(J) |

Hardness |

|---|---|---|---|---|---|

P11 |

≥ 415 |

≥ 205 |

≥ 22 |

≥ 35 |

≤ 163HB |

P12 |

≥ 415 |

≥ 220 |

≥ 22 |

≥ 35 |

≤ 163HB |

P22 |

≥ 415 |

≥ 205 |

≥ 22 |

≥ 35 |

≤ 163HB |

P5 |

≥ 415 |

≥ 205 |

≥ 22 |

≥ 35 |

≤ 187HB |

P91 |

585~760 |

≥ 415 |

≥ 20 |

≥ 35 |

≤ 250HB |

P92 |

≥ 620 |

≥ 440 |

≥ 20 |

≥ 35 |

250HB |

ASTM A335 P5, ASTM A335 P9, ASTM A335 P11, ASTM A335 P22, ASTM A335 P91 Alloy Steel Pipes Tolerance

NPS |

OD Tolerance |

NPS |

WT Tolerance |

|---|---|---|---|

1/8″ ≤ NPS ≤ 1 1/2″ |

+/- 0.4 |

1/8″ ≤ NPS ≤ 2 1/2″ , All T/D ratios. |

+20%, -12.5% |

1 1/2 < NPS ≤ 4″ |

+/- 0.79 |

NPS ≥ 2 1/2″ , T/D ≤ 5% |

+22.5%, -12.5% |

4″ < NPS ≤ 8″ |

+1.59, -0.79 |

NPS ≥ 2 1/2″ , T/D > 5% |

+15%, -12.5% |

8″ < NPS ≤ 12″ |

+2.38, -0.79 |

(T= Specified Wall Thickness; D = Specified Outside Diameter) |

|

Alloy Steel Pipes, Tubes Specifications

SAE/AMS Specifications| SAE-J356 | Welded Flash Controlled Low Carbon Steel Tubing Normalized for Bending. Double Flaring and Beading. Covers normalized electric resistance welded tube ID flash-controlled .005" to .010" manipulative quality. |

|---|---|

| SAE-J524 | Seamless Low Carbon Steel Tubing Annealed for Bending and Flaring. Covers cold drawn seamless JIC hydraulic line tubing. |

| SAE-J525 | Welded and Drawn Low Carbon Steel Tubing Annealed for Bending and Flaring. Covers welded and drawn JIC hydraulic line tubing. |

| SAE-J526 | Welded Low Carbon Steel Tubing. Covers annealed welded tube with ID flash-in for general automotive applications. |

| SAE-J527 | Brazed Double Wall Carbon Steel Tubing. Covers copper brazed double wall low carbon steel tube intended for general automotive applications and other similar uses. Suitable for bending, forming and double flaring. |

| SAE-J529 | Fuel Injection Tubing. Covers low carbon steel tube specially manufactured for high pressure fuel injection lines for diesel engines. |

| AMS-5050 | Seamless Annealed Low Carbon Steel Tube. Covers cold drawn seamless JIC hydraulic line steel tubing for aircraft applications. |

| AMS-5062 | Seamless Low Carbon Steel Tube. Covers cold finished or hot finished seamless low carbon mechanical steel tube. |

| AMS-6360 | Seamless SAE 4130 Alloy Steel Tubing. Covers aircraft quality 4130 tube in condition N temper. Similar to MIL-T-6736 specification. |

| AMS-6365 | Seamless SAE 4135 Alloy Steel Tubing. Covers aircraft quality 4135 tube in condition N temper. Similar to MIL-T-6735 specification. |

| AMS-6371 | Seamless SAE 4130 Alloy Steel Mechanical Tubing. Covers electric furnace grade magnaflux quality 4130 aircraft tube, either hot finished or cold finished, hardenable. |

| AMS-6372 | Seamless SAE 4135 Alloy Steel Mechanical Tubing. Covers electric furnace grade magnaflux quality 4135 aircraft tube, either hot finished or cold finished, hardenable. |

| AMS-6381 | Seamless SAE 4140 Alloy Steel Mechanical Tubing. Covers electric furnace grade magnaflux quality 4140 aircraft tube, either hot finished or cold finished, hardenable. |

| AMS-6415 | Seamless SAF 4340 Alloy Steel Mechanical Tubing. Covers electric furnace grade magnaflux quality 4340 aircraft tube, either hot finished or cold finished, hardenable. |

Applications Of ASTM A335 P5, ASTM A335 P9, ASTM A335 P11, ASTM A335 P22, ASTM A335 P91 Alloy Steel Pipes In Seamless & Welded Form

- Refineries

- Power Plants

- Boilers

- Ship Building

- Heat Exchangers

- Condensers

- Paper & Pulp

- Marine Applications

- Nuclear Power

- Fossil Fuel Power Plants

ASTM A335 P5, ASTM A335 P9, ASTM A335 P11, ASTM A335 P22, ASTM A335 P91 Alloy Steel Pipes Packaging & Shipping

ASTM A335 P5, ASTM A335 P9, ASTM A335 P91 Alloy Steel Pipes in Seamless & Welded both are loose or in bundles tightened with Iron Strips. Special packings: Metal or Wooden Cases, Pallets etc. Plastic closes both ends, Hexagonal bundles maximum 2.000 kg with several steel strips, Two tags on each bundle, Wrapped in waterproof paper, PVC sleeve, and IN in sackcloth with several steel strips, Plastic caps.

Both ends of each crate will indicate the order no., heat no., dimensions, weight and bundles or as requested. We can also offer customized packaging for ASTM A335 P11, ASTM A335 P22 as per customer's requirement.

Marking Requirements

Marking Requirements

Rolled, die stamped, or paint stenciled (manufacturer’s option).

- Manufacturer’s name, brand, or trademark

- ASTM A335 P91 Alloy Steel Pipes

- ANSI schedule number or weight class or wall thickness

- Additional “S” if tested supplementary requirements

- Hydrostatic test pressure and/or NDE, or NH if neither is specified

- Size, length, weight per foot (NPS 4 and larger)

Overseas Packaging

Export packaging is geared towards the protection, handling and transport of ASTM A335 P22 Alloy Steel Pipes by air or sea freight and, as such, shares many characteristics with export and transport packaging. Utmost care must also be taken to make overseas packaging suitable for long periods of storage. It is important for overseas packaging to be designed with ease of handling in mind, so as to ensure ASTM A335 P9 Alloy Steel Pipes is treated with the utmost care at all times.

Brands we Stock & Supply of ASTM A335 P5, ASTM A335 P9, ASTM A335 P11, ASTM A335 P22, ASTM A335 P91 Alloy Steel Pipes

Authorised Dealer & distributor of |

||||

|---|---|---|---|---|

United Seamless Limited -usl ASTM A335 P5, P9, P11, P22, P91 Pipes |

Bao Steel- Bao ASTM A335 P5, P9, P11, P22, P91 Pipes |

Yangzhou Lontrin Steel Tube -lontrin ASTM A335 P5, P9, P11, P22, P91 Pipes |

Sumitomo Metals Smtm ASTM A335 P5, P9, P11, P22, P91 Pipes |

Tenaris -tnrs ASTM A335 P5, P9, P11, P22, P91 Pipes |

Valourec & Mannesman -v&m ASTM A335 P5, P9, P11, P22, P91 Pipes |

Wuxi ASTM A335 P5, P9, P11, P22, P91 Pipes |

Maharastra Seamless Limited -msl ASTM A335 P5, P9, P11, P22, P91 Pipes |

Indian Seamless Metal Tubes Limited _ismt ASTM A335 P5, P9, P11, P22, P91 Pipes |

Jindal Saw Ltd -jsl ASTM A335 P5, P9, P11, P22, P91 Pipes |

We are approved vendor & Suppliers of ASTM A335 P5, ASTM A335 P9, ASTM A335 P11, ASTM A335 P22, ASTM A335 P91 Alloy Steel Pipes in GASCO, KNPC, SAUDI ARAMCO, SABIC, ORPIC, NIORDC, PIDMCO etc.

Vendor & Suppliers of |

|||||

|---|---|---|---|---|---|

GASCO |

KNPC |

SAUDI ARAMCO |

SABIC |

ORPIC |

PIDMCO |

Mumbai |

Thane |

Navi Mumbai |

Pune |

Pimpri-Chinchwad |

Vadodara |

Kolkata |

Gurgaon |

Ahmedabad |

New Delhi |

Bengaluru |

Chennai |

Surat |

Bhopal |

Ulsan |

Faridabad |

Houston |

Dubai |

Seoul |

Hyderabad |

Singapore |

Abu Dhabi |

Tehran |

Calgary |

Noida |

Riyadh |

London |

Coimbatore |

Jakarta |

Istanbul |

Bangkok |

Kuwait City |

Sharjah |

Muscat |

Edmonton |

Edmonton |

Busan |

Mexico City |

Doha |

Jeddah |

Aberdeen |

Cairo |

Geoje-si |

Perth |

Santiago |

Chandigarh |

Indore |

Kuala Lumpur |

Rio de Janeiro |

Dammam |

Melbourne |

Madrid |

La Victoria |

Bogota |

Lahore |

Los Angeles |

Algiers |

Chiyoda |

Ankara |

Ho Chi Minh City |

Toronto |

Hong Kong |

Rajkot |

Brisbane |

Petaling Jaya |

Ernakulam |

Secunderabad |

Gimhae-si |

Al Jubail |

Port-of-Spain |

Thiruvananthapuram |

Milan |

Atyrau |

Lagos |

Hanoi |

Howrah |

Sydney |

Ahvaz |

Karachi |

New York |

Caracas |

Vung Tau |

Al Khobar |

Manama |

Montreal |

Granada |

Courbevoie |

Visakhapatnam |

Ludhiana |

Moscow |

Dallas |

Haryana |

Colombo |

India |

Saudi Arabia |

Bangladesh |

United States |

UAE |

Canada |

Angola |

Argentina |

Austria |

Azerbaijan |

Pakistan |

Peru |

Chile |

Spain |

France |

United Kingdom |

Indonesia |

Israel |

Iran |

Kuwait |

Mexico |

Malaysia |

Nigeria |

Serbia |

Singapore |

Taiwan |

Chile |

Venezuela |

Ecuador |

Netherlands |

Brazil |

Colombia |

Ghana |

Iran |

Denmark |

Poland |

Australia |

Afghanistan |

Bahrain |

Costa Rica |

Egypt |

Iraq |

Jordan |

South Korea |

Kazakhstan |

Sri Lanka |

Lithuania |

Norway |

Oman |

Philippines |

Poland |

Qatar |

Russia |

Vietnam |

South Africa |

Nigeria |

Mexico |

Turkey |

Hungary |

Algeria |

Belarus |

Belgium |

Bhutan |

Bolivia |

Bulgaria |

Croatia |

Czech Republic |

Estonia |

Finland |

Greece |

Italy |

Japan |

Libya |

Romania |

Thailand |

Trinidad |

Tobago |

Tunisia |

Ukraine |

Yemen |

Hong Kong |

Gabon |

China |

Portugal |

Switzerland |

New Zealand |

Sweden |

Slovakia |

Kenya |

Lebanon |

Morocco |

Mongolia |